Chapter 8.35

NONPUBLIC WATER SUPPLY WELLS

Sections:

8.35.050 Certified contractor.

8.35.060 Nonconforming installations.

8.35.100 General construction requirements.

8.35.110 Types of well construction.

8.35.140 Disposal of drilling mud.

8.35.150 Pumps and pumping equipment.

8.35.180 Pitless adapters and pitless units.

8.35.240 Hydropneumatic (pressure) tanks.

8.35.250 Electrical connections.

8.35.260 Interconnections and cross connection.

8.35.270 Backflow prevention for chemical injection systems for nonpotable water wells.

8.35.280 Filters and water treatment equipment.

8.35.300 Water sampling and analysis.

8.35.310 Abandonment of wells.

8.35.320 Closed circuit vertical heat exchangers.

8.35.340 Refusal of admittance.

8.35.390 Conflict with state law.

8.35.010 Purpose.

The purpose of this chapter is to protect the public health by protecting groundwater supplies from contamination by establishing uniform minimum standards and methods for well construction and reconstruction for nonpublic water supply wells, by requiring permits and providing for permit fees and by establishing penalties for the violations of the provisions contained herein.

This chapter also provides minimum standards for installation of water well pumps or equipment employed in withdrawing or obtaining water from a well for any use, except monitoring wells, including such seals and safeguards as may be necessary to protect from contamination the water in the aquifer and water being pumped from the well. [Ord. passed 3/22/2023.]

8.35.020 Applicability.

The provisions contained herein apply to all nonpublic water supply wells located in the county, and constructed for the purpose of domestic, livestock, irrigation, recreation, and commercial or industrial use, for which a construction permit is issued after the effective date of the ordinance from which this chapter is derived. They shall also apply to existing water wells for which well services permits are issued for rehabilitation or reconstruction after the effective date of the ordinance from which this chapter is derived. [Ord. passed 3/22/2023.]

8.35.030 Definitions.

“Abandoned well” means a well whose use has been permanently discontinued. A well shall be considered abandoned when its condition is such that continued use is impractical or no longer desired.

“Administrative authority” means the local boards of health.

“Anaerobic lagoon” means an impoundment, the primary function of which is to store and stabilize organic wastes. The impoundment is designed to receive wastes on a regular basis, and the design waste loading rates are such that the predominant biological activity in the impoundment will be anaerobic. An anaerobic lagoon does not include:

1. A runoff control basin which collects and stores only precipitation-induced runoff from an open feedlot feeding operation; or

2. A waste slurry storage basin which receives waste discharges from confinement feeding operations and which is designed for complete removal of accumulated wastes from the basin at least semiannually; or

3. Any anaerobic treatment system which includes collection and treatment facilities for all off-gases.

“Annular space” means the open space between the well hole excavation and the well casing.

“Backflow prevention device” means any device, method or type of construction to prevent backflow of water, liquids, mixtures, or substances into a well or into the distribution pipes of a potable supply of water from any source other than its intended source.

“Cesspool” means a covered excavation, lined or unlined, into which wastes from toilets or urinals are discharged for disposal. Cesspools are not an approved method of sewage disposal.

“Class 1 well” means a well 100 feet or less in depth and 18 inches or more in diameter.

“Class 2 well” means a well more than 100 feet in depth or less than 18 inches in diameter or a bedrock well. Bedrock wells include:

1. Wells completed in a single confined aquifer;

2. Wells completed in a single unconfined aquifer; and

3. Wells completed in multiple aquifers.

“Class 3 well” means a sandpoint well 50 feet or less in depth and having a casing inside diameter of two inches or less constructed by joining a screened drive point with lengths of pipe and driving the assembly into a shallow sand and gravel aquifer.

“Compensation for well interference” means payment to the owner of a nonregulated well for damages caused by a lowered water level in the well due to withdrawal of water for a permitted use.

“Confinement building” means a building used in conjunction with a confinement feeding operation to house animals.

“Conforming well” means a well that complies with the standards of this chapter, including wells properly plugged according to 567 IAC Chapter 39.

“Construction” means the physical act or process of making a water well including, but not limited to, siting, excavation, construction and installation of equipment and materials necessary to maintain and operate the well.

“Contractor” means a person engaged in the business of well construction or reconstruction. The term may include a corporation, partnership, sole proprietorship, association or any other business entity, as well as any employee or officer of the entity.

“Deep well” means a well located and constructed in such a manner that there is a continuous layer of low permeability soil or rock at least five feet thick located at least 25 feet below the normal ground surface and above the aquifer from which water is to be drawn.

“Department” means Black Hawk County Health Department.

“Earthen manure storage basin” means an earthen cavity, either covered or uncovered, which, on a regular basis, receives waste discharges from a confinement feeding operation if accumulated wastes from the basin are completely removed at least once each year.

“Established grade” means the permanent point of contact of the ground to artificial surface with the casing or curbing of the well.

“Formed manure storage structure” means a structure, either covered or uncovered, used to store manure from a confinement feeding operation, which has walls and a floor constructed of concrete, concrete block, wood, steel, or similar materials. Similar materials may include, but are not limited to, plastic, rubber, fiberglass, or other synthetic materials. Materials used in a formed manure storage structure shall have the structural integrity to withstand expected internal and external load pressures.

“Grout” means a material used to seal the annular space between the casing and the borehole and shall consist of neat cement, concrete, high solids bentonite slurry, or hydrated bentonite chips.

“Health-related problem” means well water that contains any contaminant at a level that exceeds MCLs (maximum contaminant levels), or HALs (health advisory levels) as adopted by the Department of Natural Resources.

“Heavy drilling fluid” means water used for drilling which because of the natural clay content of the borehole or by addition of bentonite grout has a solids density of at least 10 percent by weight or a mud weight of at least nine and one-quarter pounds per gallon.

“IAC” means the Iowa Administrative Code.

“Landowner” means an individual, trust, partnership, corporation, government or governmental subdivision or agency, association or other legal entity that has legal or equitable title to a piece of land.

“Landowner’s agent” means a person who acts for or in place of the landowner by authority from the landowner.

“Low permeability material” means a geological unit of unconsolidated material (usually clay or till) or bedrock (usually shale) that is all or partially saturated, and having permeability low enough (10-7 cm/sec) to give water in the aquifer artesian head.

“Nonpublic water supply well” means a well that does not supply a public water supply system.

“Nonregulated well” means a well used to supply water for a nonregulated use (a use of water less than 25,000 gallons per day which is not required to have a water use permit).

“Open feedlot” means an unroofed or partially roofed animal feeding operation in which no crop, vegetation, or forage growth or residue cover is maintained during the period that animals are confined in the operation.

“Permitted use” means a use of water in excess of 25,000 gallons per day which requires a water use permit pursuant to 567 IAC Chapters 50 through 52, and Iowa Code Chapter 455B, Division III, Part 4.

“Pitless adapter” means a device designed for attachment to one or more openings through a well casing. It shall be constructed so as to prevent the entrance of contaminants into the well through such openings, conduct water from the well, protect the water from freezing or extremes of temperature, and provide access to water system parts within the well.

“Pitless unit” means an assembly which extends the upper end of the well casing to above grade. It shall be constructed so as to prevent the entrance of contaminants into the well, conduct water from the well, and protect the water from freezing or extremes of temperature, and shall provide full access to the well and to water system parts within the well. It shall provide a pitless well cap for the top terminal of the well.

“Public water supply” means a system for the provision to the public of piped water for human consumption, if such system has at least 15 service connections or regularly serves an average of at least 25 individuals daily at least 60 days out of the year. The term includes:

1. Any collection, treatment, storage, and distribution facilities under control of the supplier of water and used primarily in connection with the system; and

2. Any collection (including wells) or pretreatment storage facilities not under the control of the supplier which are used primarily in connection with the system.

“Pump installer” means a person certified by the Department to perform pump services.

“Pump services” means the installation, repair, and maintenance of water systems; modification of the upper terminus of a well; well plugging; well rehabilitation; or the construction of Class 3 wells.

“Pumps and pumping equipment” means any equipment or materials, including seals, tanks, fittings and controls, utilized or intended for use in withdrawing or obtaining water for any use.

“Runoff control basin” means an impoundment designed and operated to collect and store runoff from an open feedlot.

“Shallow well” means a well located and constructed in such a manner that there is not a continuous layer of low permeability soil or rock (or equivalent retarding mechanism acceptable to the Department) at least five feet thick, the top of which is located at least 25 feet below the normal ground surface and above the aquifer from which water is to be drawn.

“Stuffing box” means an approved receptacle in which packing may be compressed to form a watertight or airtight junction between two objects.

“Upper terminus” means the upper 10 feet of the well casing as measured from the finished surface grade.

“Water systems” means any part of the mechanical portion of a water well that delivers water from the well to a valve that separates the well from the plumbing system. “Water systems” includes the pump, drop pipe to the well, electrical wire from the pump to the first electrical panel or connection outside the casing, piping from the well to the pressure tank or first valve outside the casing, pitless unit or adapter, and all related miscellaneous fittings necessary to operate the pump. “Water systems” does not include any outside piping to other buildings and does not include the piping that carries the water in the remainder of the distribution system.

“Well” means any excavation that is drilled, cored, driven, dug, bored, augered, jetted, washed or is otherwise constructed for the purpose of exploring for groundwater, monitoring groundwater, utilizing the geothermal properties of the ground, or extracting water from or injecting water into the aquifer. “Well” does not include an open ditch, drain tiles, an excavation made for obtaining or prospecting for oil, natural gas, minerals, or products mined or quarried, lateral geothermal heat exchange systems less than 20 feet deep, nor temporary dewatering wells such as those used during the construction of subsurface facilities only for the duration of the construction.

“Well construction” means constructing a water well and installing necessary casing, screen, liners, grout, seals, and other appurtenances.

“Well driller” means a person certified by the Department to perform well drilling services.

“Well drilling services” means new well construction, well reconstruction, well repair, well rehabilitation, installation of pitless equipment, or well plugging.

“Well liner” means a pipe used to line the inside of a well hole but not designed to hold hydraulic or structural loading. Liners must be installed within a casing or in an ungrouted open borehole.

“Well plugging” means the closure of an abandoned well with plugging materials by procedures which will permanently seal the well from contamination by surface drainage and permanently seal off the well from contamination into an aquifer. “Well plugging” includes the proper application of filling and sealing materials.

“Well reconstruction” means modification of the original construction of a well. “Well reconstruction” includes, but is not limited to, deepening the well, installing a liner, installing, or replacing a screen with one of a different diameter or length, installing a pitless adapter, extending the casing, or hydrofracturing a well. Replacing a screen with one of identical diameter and length or replacing a pitless adapter is considered repair, not reconstruction.

“Well rehabilitation” means the physical or chemical cleaning of a well.

“Well seal” means a device used to cover or seal a well that establishes or maintains a junction between the casing of the well and the piping, electric conduit or equipment installed, so as to prevent water or other foreign material from entering the well at the uppermost terminal.

1. “Well cap” means a snug-fitting, watertight device used above flood level that excludes dust and vermin and allows for screened venting.

2. “Sanitary seal” means a watertight fitting which uses mechanical compression that is installed on wells that terminate in a wellhouse.

“Well services” means both well drilling services and pump services. [Ord. passed 3/22/2023.]

8.35.040 Well permitting.

A. The administrative authority shall have the authority to visit well sites during any phase of the work without prior notice. The administrative authority shall by rule require the issuance of permits and the submission of water well logs. No well construction or reconstruction shall be initiated until a permit has been issued by the proper authority.

B. A landowner or landowner’s agent shall not drill or construct a new private water well without first obtaining a well construction permit issued by the Health Department.

C. A private well construction permit is required for all replacement wells. A private well construction permit is required for modification to a well such as changes in physical dimensions including, but not limited to, deepening the well and changing the diameter or length of the casing or the screen. A private well construction permit is not required for the repair, maintenance, or rehabilitation of an existing well that does not change its physical dimensions.

1. A private well construction permit is not a water withdrawal permit and does not eliminate the necessity of obtaining any water withdrawal permits required in 567 IAC Chapters 50 through 54. A water withdrawal permit is required before an applicant can withdraw more than 25,000 gallons of water per day from any source or combination of sources in the state of Iowa.

D. Application for a private well construction permit shall be made on forms supplied by the Black Hawk County Health Department.

1. Each application shall list all wells, including nonplugged abandoned wells, on the applicant’s property contiguous to the well site described in the application and shall describe the location of each well site. The location shall be given in the form of a legal land description (section, township and range) to the nearest quarter of a quarter of a quarter of a section, or as a latitude and longitude in degrees to four-decimal accuracy. The list of wells to be registered shall include but is not limited to abandoned wells, inactive wells, agricultural drainage wells, irrigation wells, domestic wells and livestock wells.

E. It shall be the responsibility of the certified well contractor to ensure that a well construction permit has been issued prior to initiation of well services. It shall also be the responsibility of the certified well contractor to ensure that all well services are performed in accordance with the provisions of this chapter.

F. The Department may deny a private well construction permit if granting the permit would lead to the violation of state law, could result in groundwater contamination, would lead to withdrawal from a protected source, or the well could threaten public health or the environment.

G. A private well construction permit is not transferable.

H. A private well construction permit shall expire one calendar year from the date of issuance. If construction of the proposed well is not started prior to the expiration date, a new application plus a new nonrefundable fee must be filed with the Department. [Ord. passed 3/22/2023.]

8.35.050 Certified contractor.

A. No person, firm or corporation shall conduct any work on a well in Black Hawk County without proper certification by the Iowa Department of Natural Resources. All persons who construct, reconstruct, or plug wells must be a certified well contractor.

B. It shall be the responsibility of the certified well contractor to ensure that all well services are performed in accordance with this chapter. [Ord. passed 3/22/2023.]

8.35.060 Nonconforming installations.

A. Certified well drilling contractors shall ensure that the reconstruction of nonconforming wells adheres to all applicable provisions of this chapter or to comparable construction or installation requirements approved by the administrative authority.

B. When any construction or reconstruction is done on a nonconforming feature of a well, that feature shall be upgraded and brought into compliance with the material and installation standards contained in this chapter. [Ord. passed 3/22/2023.]

8.35.070 Exemptions.

The provisions of this chapter shall not apply to public water supply wells, horizontal heat pump installations, elevator shafts, underground storage tank monitoring wells as covered under 567 IAC Chapter 135, or monitoring wells for solid waste disposal facilities as covered in 567 IAC Chapter 110. [Ord. passed 3/22/2023.]

8.35.080 Variances.

Variances to the provisions of this chapter may be granted by the administrative authority if sufficient information is provided to substantiate equal protection and the need for such action. Variance requests and reasoning shall be in writing. Variance approvals or rejections shall also be in writing. [Ord. passed 3/22/2023.]

8.35.090 Location of wells.

A. Wells shall be located with consideration given to the lot size, contour, porosity and absorbency of the soil, local groundwater conditions, flooding, and other factors necessary to implement the rules. The lack of specific distances to other possible sources of contamination, such as refuse disposal sites and high-pressure gas lines, does not minimize their potential hazard. These must be evaluated in each particular situation and a distance arrived at that is based on pertinent facts. The well contractor shall consult the administrative authority for assistance in determining a proper distance in such cases.

1. Minimum Distances. See Table 8.35.090A(1) for the minimum lateral distances from all private wells that shall apply for the common structures or sources of contamination.

2. Exception to Minimum Lateral Distances. The minimum separation distance between a well and an anaerobic lagoon, earthen manure slurry storage basin, earthen manure storage basin, or runoff control basin shall be 400 feet if the lagoon or basin was permitted by the Department after January 1, 1989, or if the applicant demonstrates through percolation testing that the seepage loss through the lagoon or basin does not exceed one-sixteenth inch per day. The percolation test shall meet the requirements of ASTM-1587 and 567 IAC Subrule 65.15(11).

3. Frost Pits. Wells are not permitted to be located within frost pits. Frost pits that do not contain wells are permitted for the purpose of housing pressure tanks and valves, for example, provided the frost pits are not located closer than 10 feet from any well.

4. Relation to Buildings. The well shall be located so that no building interferes with reasonable access for cleaning, treatment, repair, testing, inspection and other maintenance. Wells shall not be located in basements.

5. Easements. No well shall be located on a property not owned by the well owner unless an easement allowing such placement is reviewed and approved by the administrative authority and the easement is legally recorded.

|

Structure or Source of Contamination |

Minimum Lateral Distance (Feet) |

|

|---|---|---|

|

Shallow Well1 |

Deep Well1 |

|

|

Public water supply well |

400 |

200 |

|

Formed manure storage structure, confinement building, feedlot solids settling facility, open feedlot |

200 |

100 |

|

Transmission pipelines (including, but not limited to, fertilizer, liquid petroleum, or anhydrous ammonia) if a more restrictive setback is not set by the pipeline owner |

200 |

100 |

|

|

All Private Wells |

|

|

Earthen manure storage basin, runoff control basins and anaerobic lagoons (see 567 IAC Subrule 49.6(2)) |

1,000 |

|

|

Drainage wells |

1,000 |

|

|

Solid waste landfills and disposal sites2 |

1,000 |

|

|

Domestic wastewater lagoon |

400 |

|

|

Preparation or storage area for spray materials, commercial fertilizers or chemicals that may result in groundwater contamination |

150 |

|

|

Existing wells that do not conform to this chapter |

100 |

|

|

Liquid hydrocarbon storage tanks, except for liquid propane gas (LPG) |

100 |

|

|

Private sewage disposal systems – Open portion of treatment system3 |

100 |

|

|

Private sewage disposal systems – Closed portion of treatment system3 |

50 |

|

|

Flowing streams or other surface water bodies |

25 |

|

|

LPG storage tanks |

15 |

|

|

Roadside ditch and road rights-of-way |

15 |

|

|

Existing wells that conform to this chapter |

10 |

|

|

Sewer of cast iron with leaded or mechanical joints, sewer of plastic pipe with glued or compression joints, independent clear water drains, cisterns, well pits, or pump house floor drains |

10 |

|

|

Yard hydrants |

10 |

|

|

Frost pit |

10 |

|

|

Property lines (unless a mutual easement is signed and recorded by both parties) |

4 |

|

1 “Deep well” and “shallow well” are defined in BHCC 8.35.030.

2 “Solid waste” means garbage, refuse, rubbish, and other similar discarded solid or semisolid materials, including but not limited to such materials resulting from industrial, commercial, agricultural, and domestic activities.

3 Private sewage disposal system is defined in 567 IAC Subrule 69.1(2). Open portions of treatment systems include subsurface absorption systems, mound systems, intermittent sand filters, constructed wetlands, open bottom media filters, and waste stabilization ponds. Closed portions of treatment systems include septic tanks, aerobic treatment units, fully contained media filters, and impervious vault toilets. These separation distances also apply to septic systems that are not considered privately owned.

[Ord. passed 3/22/2023.]

8.35.100 General construction requirements.

Wells shall be planned and constructed to adapt to the geologic and groundwater conditions of the proposed well site to ensure reasonable utilization of every natural protection against contamination of the water-bearing formation(s) and the exclusion of possible sources of contamination, to attempt to produce bacterially safe water which is free of health-related problems.

A. Water Used in Construction. Water used in the construction process shall be obtained from a potable water source that will not result in contamination of the well. Water used for drilling shall be treated with three pints of five and one-quarter percent sodium hypochlorite solution per 100 gallons of water or one-quarter pound of 65 percent calcium hypochlorite per 100 gallons of water or other additives to produce an equivalent concentration of chlorine residual (50 ppm).

B. Wellhead. The upper terminal casing of all wells shall extend at least 12 inches above established grade or pump house floor, or the 100-year flood level, whichever is higher. A well cap or sanitary seal shall be installed immediately following well completion. A well cap shall be used on an exposed well, a sanitary seal only on a well terminating within a wellhouse. Any openings in the cap or seal, such as for pump wiring or water depth measurement, shall be properly grommeted or sealed except properly screened and oriented vent openings.

1. The ground surface immediately adjacent to the well casing shall be compacted and graded so that surface water is diverted away from the casing. Well platforms are not recommended other than those used as pump house floors as indicated in subsection (B) of this section.

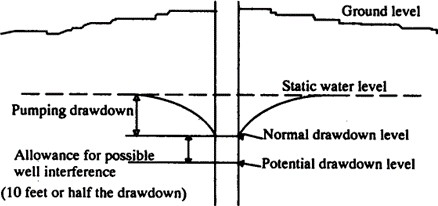

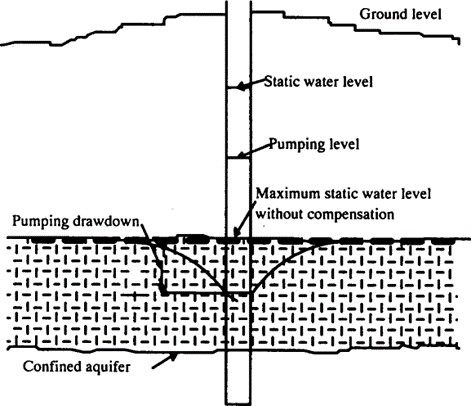

C. Criteria for Well Interference Protection. 567 IAC Chapter 54 provides an administrative process for owners of nonregulated wells to receive compensation for well interference caused by permitted uses. To be eligible for compensation due to well interference, nonregulated wells constructed after July 1, 1986, must be constructed to allow for some potential well interference.

1. Allowance for potential well interference is accomplished by constructing a nonregulated well to anticipate a lowering of the static head of the well which may be caused by interference from a nearby permitted use well (see Table 8.35.100A(2)).

2. The well design also needs to consider drought and reduced well efficiency. (Additional information is contained in 567 IAC Chapter 54.)

3. A well that is used to withdraw more than 25,000 gallons of water per day requires a water use permit from the Iowa Department of Natural Resources.

4. Upon obtaining such a permit, the well is called a permitted use. If a permitted use exists prior to the construction of a well without a water use permit, no compensation for well interference will be allowed unless a significant change in the permitted use occurs. A physical change to withdrawal facilities may be considered a significant change to a permitted use (e.g., moving the withdrawal location, installing a new well, or installing a higher capacity pump). A person desiring to construct a well not requiring a water use permit should first obtain information concerning nearby permitted use wells. The Department of Natural Resources will provide information on permitted use wells upon request.

|

a. The well must be drilled deep enough to allow for setting the pump at least 10 feet or half the normal pumping drawdown, whichever is greater, below the initial recommended setting depth. |

|

|

b. If the well draws from an unconfined aquifer, the static water level may drop to half the saturated thickness of the aquifer before well interference is considered, if the calculation in “a” above should indicate a shallower depth. Shallow aquifers that are only slightly confined may be classified as unconfined aquifers for this purpose. |

|

|

c. Where a well penetrates a confined aquifer, the static water level is protected only to the top of the aquifer if the calculation in “a” above should indicate a deeper level. |

|

|

d. Protected levels for flowing wells will be considered the top of the confined aquifer or 100 feet below the surface, whichever is higher. Flowing wells must be constructed to accommodate a pump capable of supplying a sufficient water supply at protected levels. |

D. Access Port for Measurement of Water Levels. Permitted use wells shall be equipped with an access port having a minimum diameter of three-quarters of an inch. The access port shall be fitted with a threaded cap or plug and be located to allow insertion of a steel tape or electric probe into the well for measurement of water levels. When a spool type of pitless adapter is used which obstructs clear access to the water, a three-quarter-inch pipe shall be attached to the spool and brought to the surface below the well cap to allow water level measurements. Wells not requiring a water use permit should be constructed with an access port for water level measurement for possible future well interference concerns.

E. Interconnection of Aquifers. There may be local confining beds that serve an important protective function. Permitted use wells shall use casing and grouting to maintain a hydraulic separation between distinct aquifers separated by confining intervals. Extreme caution should be exercised in the construction of nonpermitted use wells if allowing the well to connect aquifers across confining intervals, particularly in areas where that would open the aquifer to surficial contamination, i.e., in areas where the upper rock unit is unconfined or contains less than 40 feet of unconsolidated materials. The administrative authority shall be consulted for possible local regulations when interconnection of aquifers across confining intervals is anticipated. [Ord. passed 3/22/2023.]

8.35.110 Types of well construction.

A. Drilled Wells in Unconsolidated Materials.

1. Depth. In no case shall less than 20 feet of permanent casing be installed in wells drilled in unconsolidated materials. If the alluvial aquifer where the water is to be drawn from is covered by less than 40 feet of low permeability materials, the well screen shall be set at the bottom of the water-bearing aquifer or at least 60 feet from the surface. (Deeper depths may be required if nitrate contamination is excessive.) If more than 40 feet of low permeability materials are present above the aquifer, the casing shall extend down at least to the top of the aquifer.

2. Grouting. Grout shall be placed to a minimum depth of 40 feet or along the full length of the casing where less than 40 feet of casing is set. Grouting the full length of the casing below 40 feet may be necessary to isolate any contaminated water lenses or aquifers. If a layer of low permeability material at least five feet thick is encountered less than 40 feet from the surface, the grout may be terminated no less than five feet below the top of this low permeability material, but in no case less than 20 feet from the ground surface. Grout must be placed in accordance with BHCC 8.35.120(D), except when driving casing. When driving casing a number 8 mesh bentonite or bentonite grout must be maintained around the outside of the casing. The bottom of driven casing must be equipped with a drive shoe.

3. Annular Space. The diameter of the borehole shall be at least three inches greater than the outside diameter of the well casing to the minimum grouting depth. When steel well casing pipe is installed using percussion methods, the annular space shall be at least five inches greater than the outside diameter of the well casing to a minimum depth of 25 feet.

4. If the depth of casing is greater than 40 feet, the annular space below 40 feet may be filled with heavy drilling fluid taken from the borehole as long as the top 40 feet of annular space is properly grouted. In this case, the annular space below 40 feet shall be kept as small as possible to avoid settling.

B. Drilled Wells in Consolidated Materials.

1. Minimum Casing Depth. Casing shall extend to a depth of at least 40 feet and be seated in firm rock. When the uppermost bedrock consists of creviced limestone or dolomite that does not produce water, the casing shall extend through the creviced formation, be seated in firm rock and be properly grouted.

2. Grouting. For bedrock wells, full-length grouting of the casing is strongly recommended. Grout shall be placed to a minimum depth of 40 feet in accordance with BHCC 8.35.120(D), except when driving casing using percussion or casing-hammer/rotary drilling. When driving casing, number 8 mesh bentonite or bentonite grout must be maintained around the outside of the casing. The bottom of driven casing must be equipped with a drive shoe. If a layer of low permeability material at least five feet thick is encountered less than 40 feet from the surface, the grout may be terminated no less than five feet below the top of this low permeability material, but in no case less than 20 feet from the ground surface. Where local conditions warrant, the administrative authority may require more extensive grouting to protect any aquifer(s) that are penetrated.

3. Annular Space. The borehole shall be at least three inches greater than the outside diameter of the well casing for the upper 40 feet or the minimum grouting depth. When steel casing pipe is installed using percussion, or casing-hammer/rotary methods, the annular space shall be at least five inches greater than the outside diameter of the well casing to a minimum depth of 25 feet. When bedrock wells are full-length pressure-grouted through the casing, the borehole diameter shall be three inches larger than the outside diameter of the casing for the minimum depth of at least 25 feet.

4. If the depth of casing is greater than 40 feet, the annular space below 40 feet may be filled with heavy drilling fluid taken from the borehole as long as the top 40 feet of annular space is properly grouted.

5. In fractured rock, where circulation of slurry cannot be maintained, grouting may be done with bentonite chips. The chips shall be hydrated with one gallon of water per bag of bentonite.

C. Bored and Augered Wells in Unconsolidated Materials.

1. For bored or augered wells with concrete or clay tile casings at least 18 inches in diameter, buried-slab construction is required.

2. Casing. The concrete or vitrified clay pipe casing shall be terminated not less than 10 feet below ground surface and extend to a minimum depth of 20 feet. The casing shall be fitted with a reinforced concrete or steel plate into which a watertight steel or thermoplastic casing is firmly imbedded in or connected to a pipe cast or welded into the plate. This casing shall be at least five inches in diameter and shall extend from the plate to not less than 12 inches above established grade or the 100-year flood level, whichever is higher. A pitless adapter shall be installed below frost depth on the newly installed plastic or steel casing.

3. Backfilling Annular Space. A 12-inch grout seal shall be poured over and around the plate. The annular space between the steel or thermoplastic casing and the borehole shall be backfilled with clean compacted soil free of debris or large organic material. During the backfilling process, the earth shall be thoroughly tamped to minimize settling. Grading around the well shall then be accomplished in accordance with BHCC 8.35.100(B).

D. Driven and Direct Push Wells.

1. Sandpoint wells are typically constructed in sandy areas with a high water table. Groundwater in these areas is often susceptible to contamination. This type of construction is not recommended for potable water supply. Sandpoint wells shall meet the requirements of this chapter except for casing depth and grouting requirements.

E. Flowing Artesian Wells.

1. Drilling operations shall extend into but not through the formation confining the water. The casing shall then be installed and the annular space full-length pressure-grouted and allowed to set. After the grout is set, the drill hole shall be extended into the confined water-bearing formation. Flow control from the well shall be provided by valved pipe connections or a receiving tank set at an altitude corresponding to that of the artesian head. Under no circumstances shall the water flow uncontrolled to waste. A direct connection between the discharge pipe and a receiving tank, sewer, or other source of contamination is prohibited. [Ord. passed 3/22/2023.]

8.35.120 Material standards.

All materials utilized in well water construction shall conform to the standards of the American Water Works Association (AWWA), the American Petroleum Institute (API), the American Society for Testing and Materials (ASTM), and the National Ground Water Association (NGWA) except as modified by these standards.

A. Water Well Casing.

1. Steel Well Casing and Couplings.

a. Steel well casing pipe shall have the dimensions and weights specified in Table 8.35.120A(3). Well casing pipe shall be new steel pipe meeting one of the following standards:

i. ASTM A 53-96;

ii. ASTM A 106-95;

iii. ASTM A 589-95a – Type I, II or III;

iv. API 5CT (5th Edition, 4/1/95);

v. API 5D (3rd Edition, 8/1/92); or

vi. API 5L (41st Edition, 4/1/95).

(Copies of these standards are available for inspection at the Des Moines office of the Department of Natural Resources records center or may be obtained for personal use from the American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, Pennsylvania 19428-2959, or the American Petroleum Institute, 1220 L Street NW, Washington, DC 20005.)

b. Each length of casing shall be legibly marked in accordance with API or ASTM marking specifications showing the manufacturer’s or processor’s name or trademark, size in inches, weight in pounds per foot, whether seamless or welded (type of weld) and the API or ASTM specification or trade monogram.

c. All casing pipe joints shall be watertight welded construction or threaded couplings.

d. Minimum casing pipe and coupling weights and dimensions are as follows:

|

Size (inches) |

Weight (lbs/ft) |

Pipe |

Couplings |

|||||

|---|---|---|---|---|---|---|---|---|

|

Threads & Coupling |

Plain End |

Thickness (inches) |

External Diameter (inches) |

Internal Diameter (inches) |

Threads Per Inch |

External Diameter (inches) |

Length (inches) |

|

|

1 |

1.70 |

1.68 |

.133 |

1.315 |

1.049 |

11-1/2 |

1.576 |

2-5/8 |

|

1-1/4 |

2.30 |

2.27 |

.140 |

1.660 |

1.380 |

11-1/2 |

1.900 |

2-3/4 |

|

1-1/2 |

2.75 |

2.72 |

.145 |

1.900 |

1.610 |

11-1/2 |

2.200 |

2-3/4 |

|

2 |

3.75 |

3.65 |

.154 |

2.375 |

2.067 |

11-1/2 |

2.750 |

2-7/8 |

|

2-1/2 |

5.90 |

5.79 |

.203 |

2.875 |

2.469 |

8 |

3.250 |

3-15/16 |

|

3 |

7.70 |

7.58 |

.216 |

3.500 |

3.068 |

8 |

4.000 |

4-1/16 |

|

3-1/2 |

9.25 |

9.11 |

.226 |

4.000 |

3.548 |

8 |

4.625 |

4-3/16 |

|

4 |

11.00 |

10.79 |

.237 |

4.500 |

4.026 |

8 |

5.200 |

4-5/16 |

|

5 |

15.00 |

14.62 |

.258 |

5.563 |

5.047 |

8 |

6.296 |

4-1/2 |

|

6 |

19.46 |

18.97 |

.280 |

6.625 |

6.065 |

8 |

7.390 |

4-11/16 |

|

6-5/8 OD |

20.00 |

19.49 |

.288 |

6.625 |

6.049 |

8 |

7.390 |

4-11/16 |

|

7 OD |

20.00 |

19.54 |

.272 |

7.000 |

6.366 |

8 R |

7.657 |

4-11/16 |

|

8 |

29.35 |

28.55 |

.322 |

8.625 |

8.071 |

8 |

9.625 |

5-1/16 |

|

10 |

41.85 |

40.48 |

.365 |

10.750 |

10.136 |

8 |

11.750 |

5-9/16 |

|

12 |

51.15 |

49.56 |

.375 |

12.750 |

12.090 |

8 |

14.000 |

5-15/16 |

|

14 OD |

57.00 |

54.57 |

.375 |

14.000 |

13.250 |

8 |

15.000 |

6-3/8 |

|

16 OD |

65.30 |

62.58 |

.375 |

16.000 |

15.250 |

8 |

17.000 |

6-3/4 |

|

18 OD |

73.00 |

70.59 |

.375 |

18.000 |

17.250 |

8 |

19.000 |

7-1/8 |

|

20 OD |

81.00 |

78.60 |

.375 |

20.000 |

19.250 |

8 |

21.000 |

7-5/8 |

R = Round Threads

B. Thermoplastic Casing and Couplings.

1. Materials. Thermoplastic well casing pipe and couplings shall be new polyvinyl chloride (PVC) or acrylonitrile-butadiene-styrene (ABS) material produced to and meeting the ASTM F 480 standard and shall have a standard dimension ratio (SDR) of 21, 17, or 13.5, a dimension ratio (DR) of 18 or 14, or a schedule 40 or 80 rating depending upon the specification. Styrene-rubber thermoplastic well casing pipe, including ASTM F 480, may not be used.

2. Potable Water Standards. The thermoplastic well casing pipe, pipe couplings, cement, primer and other components used shall be approved for well casing pipe in potable water supplies by the NSF Standard Number 61 or the health effects portion of Standard Number 14 as they relate to well casing pipe, or an approved equivalent organization.

3. Markings. Each length of casing shall be legibly marked showing the manufacturer’s or processor’s name or trademark, size in inches, and the ASTM F 480 specification or trade monogram.

4. Casing Joints. The thermoplastic pipe shall be assembled with either flush-threaded joints, integral-bell, solvent-cemented joints, one-piece solvent-cemented couplings or nonmetallic restrained joint system in a manner according to the specifications in ASTM F 480.

5. Hydraulic Collapse Pressure for Plastic Casing. The following table (8.35.120B(4)) provides specifications for maximum hydraulic collapse pressure (in feet of water head) to which PVC well casing of different strengths can be installed.

|

ASTM F 480 or ASTM 2241 |

C-900 |

ASTM 1785 |

|||||

|---|---|---|---|---|---|---|---|

|

SIZE |

SDR 21 |

SDR 17 |

SDR 13.5 |

DR 18 |

DR 14 |

SCH. 40 |

SCH. 80 |

|

4" |

257' |

496' |

1,024' |

— |

— |

353' |

1,055' |

|

4½" |

257' |

496' |

1,024' |

— |

— |

— |

— |

|

5" |

257' |

496' |

1,024' |

— |

— |

236' |

758' |

|

6" |

257' |

496' |

1,024' |

490' |

956' |

177' |

678' |

|

8" |

257' |

496' |

1,024' |

490' |

956' |

121' |

471' |

|

10" |

257' |

496' |

1,024' |

490' |

956' |

90' |

404' |

|

12" |

257' |

496' |

1,024' |

490' |

956' |

74' |

376' |

|

16" |

257' |

496' |

1,024' |

490' |

956' |

70' |

350' |

(1) Determined by formulae in ASTM F 480 with Poisson’s ratio of .38.

6. When cement grout is used with thermoplastic casing, the manufacturer’s specifications for use shall be followed except in the top 40 feet.

7. Thermoplastic pipe extending above ground shall be protected from ultraviolet light exposure.

8. Under no circumstances shall thermoplastic water well casing be driven.

C. Grouting Guides. Casing that is to be grouted shall have a minimum of two sets of centering guides attached to the casing so as to permit the unobstructed flow and deposition of grout.

D. Grouting. Materials and procedures for grouting shall be as follows:

1. Concrete Grout. The mixture, used with bored and augered wells, shall consist of cement, sand aggregate and water, in the proportion of one bag cement (94 pounds) and an equal volume of aggregate to not more than six gallons of clean water. Concrete grout shall not be used below the water table. Admixtures to reduce permeability or control setting time must meet ASTM Standard C 494-92. Concrete grout may be used with permission of the administrative authority where large void spaces need to be filled.

2. Neat Cement Grout. The mixture shall consist of one bag of cement (94 pounds) to not more than six gallons of clean water. Admixtures to reduce permeability or control setting time must meet ASTM Standard C 494-92.

3. Bentonite Grout. This is a mixture of water and commercial sodium-bentonite clay manufactured for the purpose of water well grouting. Mixing shall be per manufacturer’s specifications. Sodium-bentonite mixtures that have high viscosity but contain less than 10 percent solids are designed for drilling purposes and shall not be used as grout. Organic polymers used in grout mixtures must meet NSF Standard 60.

4. Exclusion. Drilling fluids and cuttings may not be used as grouting material to satisfy the minimum grouting requirements.

5. Application. Grouting shall be performed by pumping the mixture into the annular space from the bottom upward through the casing or through a tremie pipe until the annular space is filled. Grouting shall be done in one continuous operation, if possible. The bottom of the tremie pipe must remain submerged in grout while grouting.

6. Exceptions. The exceptions to this method of application are the use of buried-slab, percussion, or casing-hammer/rotary methods to construct a well. The proper grouting methods for these types of wells are specified in BHCC 8.35.110. Another exception is where dry bentonite is required because circulation cannot be maintained as described in Table 8.35.120B(4). [Ord. passed 3/22/2023.]

8.35.130 Well reconstruction.

A. All well reconstruction must meet the requirements of this chapter. If the well feature in need of reconstruction cannot be brought into compliance with these rules, the well must be properly plugged.

B. Installing a Liner. If the reconstruction will involve the placement of a liner, the certified well contractor must then determine whether the proposed reconstruction will be done in order to correct a health-related problem. The work to be performed must then be done in accordance with subsection (B)(1) or (2) of this section.

1. Standards for Installation of a Liner to Correct a Health-Related Problem.

a. The liner shall have a minimum of two sets of centering guides to allow the proper placement of grout. In no case shall the liner be driven into place.

b. The liner shall extend to the ground surface or top of the pitless adapter.

c. The annular space between the old casing and the liner shall be pressure-grouted in place throughout its entire length using an approved grout.

2. Standards for Installation of a Liner to Correct a Problem That Is Not Health Related.

a. The liner shall extend at least 10 feet above the static water level or, if a caving zone is present, shall extend above this region.

b. The liner may be pressure-grouted in place if there is a sufficient annular space for proper application of the grout.

C. Liner Material Standards. Liners must meet well casing standards as defined in BHCC 8.35.120(A). Liners may be composed of either steel or thermoplastic with a minimum inside diameter of four inches. Steel liners must be new and have a minimum wall thickness of .188 inches. Plastic liners must have a standard dimension ratio of 26 or less or a schedule rating of SCH 40 or SCH 80. If the installation does not meet the definition of a liner, then casing material shall be used.

D. Upper Terminus. All well reconstruction performed on the upper terminus of a well must meet the standards of this chapter. [Ord. passed 3/22/2023.]

8.35.140 Disposal of drilling mud.

Drilling fluid and mud remaining after construction of a well shall not be disposed of in a stream or storm sewer nor shall these materials be discharged into a sanitary sewer without permission of the owner and operator of the wastewater treatment facility. [Ord. passed 3/22/2023.]

8.35.150 Pumps and pumping equipment.

A. General Pump Installation Requirements. The installation of pumps shall be planned and carried out so the pump will be:

1. Installed so that it and its surroundings are not exposed to chemical or biological contamination;

2. Properly sized so as to provide the volume of water necessary, where obtainable, for an adequate water supply;

3. Designed to meet the well characteristics and not exceed the yield of the well except for low yield seepage/storage wells;

4. Installed for operation without repriming or breaking suction;

5. Installed in such a manner as to provide adequate protection against contamination of the water supply from any surface or subsurface sources;

6. Installed in a manner so that it is accessible for maintenance, repair, and removal.

B. Lubrication. Pump motor lubricant or coolant oil shall be United States Department of Agriculture- or United States Food and Drug Administration-approved food contact grade formulations.

C. Other Power Pumps. Other power pumps located over the well shall be mechanically joined to the casing or on a pump foundation or stand in such a manner as to effectively seal the top of the well. A sanitary seal shall be used where the pump is not located over the well, and the pump delivery or suction pipe emerges from the top.

D. Hand Pumps or Similar Devices.

1. A hand pump, hand pump head, hand pump stand or similar device shall be constructed so that there are no openings into the interior of the pump or well casing where rain water, insects or vermin can enter. Hand pumps shall be provided with a casing vent as defined in BHCC 8.35.200 and shall have a closed, downward-directed spout and a sealed pump rod packing assembly.

2. A hand pump shall be attached to a well casing by a sealed flange or other method approved by the administrative authority to adequately prevent the entrance of surface water, dirt, animals, insects, or other foreign matter. The flange shall not be less than 12 inches above a concrete slab or the ground surface.

3. Where a well casing functions as a hand pump cylinder wall, the plunger shall not be less than 25 feet below the ground surface. A casing wall weep hole is not permitted. [Ord. passed 3/22/2023.]

8.35.160 Drop pipe.

A. Discharge Pipe. Galvanized, black, or stainless steel drop pipe shall be minimum schedule 40 wall thickness. PVC drop pipe shall be minimum schedule 80 wall thickness. Schedule 80 machined PVC, brass, or stainless steel couplings shall be used with PVC pipe. Polyethylene drop pipe shall be minimum ASTM Standard PE3406 SDR9. Only brass or stainless steel fittings are permitted for use on polyethylene drop pipe. If polyethylene drop pipe is used, the outside diameter of the pump must be at least one inch smaller than the inside diameter of the well casing.

B. Check Valve. For potable water installations, all pumps shall have a check valve within 20 feet of the pump for pump installations without drain-back aeration. For pump installations with drain-back aeration, the check valve shall be below the pitless adapter. [Ord. passed 3/22/2023.]

8.35.170 Pump wiring.

Pump wiring within the well shall be double-jacketed copper wire and shall meet the National Electrical Code specifications for wire sizing, unless the pump manufacturer requires a nonjacketed wire. Wire outside of the casing must meet, at a minimum, National Electrical Code specifications. Wire shall be secured to the drop pipe at a minimum of 20-foot intervals. [Ord. passed 3/22/2023.]

8.35.180 Pitless adapters and pitless units.

A. Pitless adapters and pitless units conforming to Pitless Adapter Standard – 1997 (PAS-97) as promulgated by the Water Systems Council are considered as complying with these rules. A copy of the standard is available for inspection at the Des Moines office of the Department of Natural Resources records center or may be obtained for personal use from the Pitless Adapter Division, Water Systems Council, 1101 30th Street, NW, Suite 500, Washington, DC 20007.

B. No well casing shall be cut off or cut into below ground surface except to install a pitless well adapter below the frost level.

C. A pitless subsurface pipe connection to a well casing pipe shall be made with a weld-on, clamp-on, or bolt-on pitless adapter or weld-on or threaded pitless unit. Aboveground discharge pitless adapters with a drain-back into the well are prohibited on systems under continuous pressure.

D. If the pitless adapter is gasketed, the opening in the casing shall be sawed to the diameter recommended by the manufacturer with a hole saw and not cut with a torch. The pitless adapter used shall have the correct curvature to fit the diameter of the casing. [Ord. passed 3/22/2023.]

8.35.190 Well caps and seals.

A. A well cap shall be used on any well not protected by a wellhouse and must seal tightly against the casing to exclude surface water, dirt, insects or any foreign matter from entering the well. The well casing shall terminate at least one foot above the finished grade surface. A split-top sanitary seal may only be used on a well terminating within a wellhouse. Any openings in the cap or seal, such as for pump wiring, water depth measurement, or chemical feed, shall be properly grommeted or sealed, except properly screened and oriented vent openings. There shall be no openings through the well cap except for a factory-installed vent, air line chemical feed, and power supply wiring, unless a proposal is submitted to and approved by the administrative authority. To be approved, the proposal must show that any entrance into the well cap is watertight and meets the following conditions: prevents surface water from entering the water supply, is secured in position, is removable with tools only, and is resistant to weathering and corrosion.

B. Well pump systems that are not under continuous pressure and have no pressure tank may discharge out of the top of the well if all connections are watertight welds or grommeted openings. Venting, heights and other cap requirements shall be met. [Ord. passed 3/22/2023.]

8.35.200 Vents.

A well cap used on a well that has a pitless adapter or pitless unit must have a screened vent hole, pointing downward, with not less than 24-mesh noncorrosive screen, and that is at least one-half inch in diameter. Vent openings shall terminate at least 12 inches above finished ground surface. Venting is required on all wells except Class 3 wells or flowing water wells. [Ord. passed 3/22/2023.]

8.35.210 Underground piping.

Underground piping from the well casing to the pressure tank shall be a minimum 100 psi pressure rating, NSF Standard 61, and meet ASTM standards for potable water. [Ord. passed 3/22/2023.]

8.35.220 Underground wiring.

Underground wiring from the well shall be enclosed in a watertight electrical conduit extending from the entrance of the conduit into the casing to a minimum of three feet below ground level, threaded into the well cap, or sealed into the cap or casing in a watertight manner. The internal passage of the conduit shall be sealed around the wire with a nonhardening, pliable sealing compound. [Ord. passed 3/22/2023.]

8.35.230 Sampling faucets.

In all pressure water systems, provision shall be made for collection of water samples directly from the well by installation of a sampling faucet before the pressure tank, and prior to encountering any water treatment equipment. The sampling faucet shall be installed at least 12 inches above the floor, have a downturned spout and be in an accessible location. All sample faucets shall be metal and have a smooth (nonthreaded) outlet. [Ord. passed 3/22/2023.]

8.35.240 Hydropneumatic (pressure) tanks.

A. Sizing. The pressure tank shall have an effective water volume large enough to require the well pump to operate at least one minute between low-pressure activation and high-pressure shut off while no water is being used by the system. The minimum allowable pressure at the pressure tank shall be 30 psi.

B. Constant Pressure Pump. Constant pressure/variable speed pumps shall operate at a minimum pressure of 30 psi. Pressure tank size shall be according to manufacturer’s recommendation.

C. Pressure Relief Valve. The tank shall have a pressure relief valve of a size based on the pump capacity if the pump is capable of developing pressure greater than the working pressure of any component of the system. The pressure relief valve shall be located prior to any shut-off valve on the distribution system side of the tank.

D. Pressure Gauge. The pressure tank shall have a pressure gauge capable of reading at least 100 psi.

E. Tank Appurtenances. If a nonbladder tank is used, it shall be equipped with a means of adding or venting air from the tank to maintain the proper air-water ratio.

F. Tank Location. Buried pressure tanks shall not be permitted after July 1, 2009. If pressure tanks are not located in a residence or other heated structure, they should be housed in the following manner:

1. Buried Vault (Frost Pit). The vault and vault opening shall be sized to allow ease of access for the installation and maintenance of necessary equipment. The vault shall be as watertight as possible. The outside of the vault should be completely tiled at the base and either drain to daylight or to a sump pit that is equipped with a sump pump. The trench should be backfilled with pea gravel to one foot above the tile. All wiring in the vault shall be in watertight conduit. No buried vault shall be allowed within a 100-year floodplain. Buried vaults are not recommended because of the hazard associated with confined space entry.

2. Aboveground Structure. The structure and access opening shall be sized to allow the installation and maintenance of necessary equipment with a minimum of inconvenience. The structure shall be of an all-seasons design. It shall be insulated and heated to prevent freezing of the tank. If a poured concrete floor is provided, the top of the floor shall be at least four inches above the surrounding ground and be sloped to a drain or to the door to facilitate drainage of the room. It is recommended that the structure be located no closer than 10 feet from the well. If the structure is located over the well, it must have a hinged roof or removable hatch over the well or have other provisions for pulling the well pump. [Ord. passed 3/22/2023.]

8.35.250 Electrical connections.

At a minimum, all electrical installation shall be performed and maintained in accordance with the current National Electrical Code. A certified pump installer may perform wiring from the pump to the electrical panel unless local ordinances require additional licensing. [Ord. passed 3/22/2023.]

8.35.260 Interconnections and cross connection.

A. No connection between a well or boring and another well, boring, water supply system, any chemical injection or contamination source is allowed unless the connection is:

1. Protected by an air gap;

2. Protected by a backflow prevention device; or

3. Between wells or borings that meet the construction standards of this chapter, are used for the same purpose, and have equivalent quality water supply. [Ord. passed 3/22/2023.]

8.35.270 Backflow prevention for chemical injection systems for nonpotable water wells.

A. Backflow Protection for Irrigation. Where a chemical injection system is connected directly to a water well used for irrigation and that is not used as a potable water supply, a single-check spring- loaded backflow preventer shall be installed between the point of chemical injection on the pump discharge piping and the water well in accordance with the manufacturer’s instructions. The check valve shall withstand a minimum hydraulic pressure of 150 psi without leaking. The backflow device shall be provided with the following:

1. Valving so that water can be drained from the system to prevent freezing.

2. A vacuum relief valve to prevent backsiphoning of chemicals into the well.

3. An automatic low-pressure drain at least three-quarter inches in diameter, positioned so that when draining occurs liquid will flow away from the well. The low-pressure drain shall be at least six inches above grade. The automatic low-pressure drain shall quickly drain the check valve body of water when operation of the water well pump is discontinued.

4. A watertight seal around the check valve.

5. An inspection port four inches in diameter to allow inspection of the operation of the check valve.

B. Pump Control Interconnection. The water well pump and the chemical injection pump shall be electrically connected so that, when the water well pump stops, the chemical pump will shut off automatically. [Ord. passed 3/22/2023.]

8.35.280 Filters and water treatment equipment.1

Filters and water treatment equipment shall be installed and operated in accordance with manufacturers’ directions. [Ord. passed 3/22/2023.]

8.35.290 Well disinfection.

A. All new, repaired or rehabilitated wells shall be pumped to waste until the water is free of drilling mud, drill cuttings and sand, and the water is clear. Wells and water systems shall be disinfected by the contractor following completion of construction and whenever any well services have been performed. A chlorine solution such as a sodium or calcium hypochlorite shall be used. Chlorine compounds used for well disinfection must meet NSF Standard 61 and have no additives.

B. The disinfectant shall be dispersed throughout the entire water column in the well. The disinfectant shall also be brought into contact with the inside of the well casing pipe above the static water level.

C. The disinfectant shall remain in the well for a minimum of two hours if a concentration of at least 100 mg/L chlorine is achieved, or a minimum of 24 hours if at least 50 mg/L is achieved.

D. For emergency situations, a contact time of a minimum of 30 minutes shall be provided at a chlorine concentration of at least 200 mg/L.

E. The amount of HTH or household bleach required for a chlorine concentration of 200 mg/L is given in the following table:

|

Well casing diameter (in inches) |

4 |

6 |

8 |

12 |

18 |

24 |

30 |

36 |

|---|---|---|---|---|---|---|---|---|

|

Amount of pelleted HTH (in ounces containing approx. 70 percent Ca(OCl)2) |

0.7 |

1.5 |

2.6 |

5.6 |

13 |

23 |

36 |

52 |

|

Amount of chlorine bleach (in pints containing 5.25 percent NaOCl) |

0.5 |

1.2 |

2.1 |

4.7 |

10.6 |

18.8 |

29.3 |

42.2 |

F. Dry disinfectant shall be dissolved in a separate container of water before introduction into the well. The solution shall contain not more than eight ounces of pelleted HTH disinfectant per five gallons of water. [Ord. passed 3/22/2023.]

8.35.300 Water sampling and analysis.

A. The owner of a new, reconstructed, or rehabilitated well shall be responsible for submitting a water sample to a certified laboratory for coliform bacteria and nitrate analysis. The water sample shall be collected at least 10 days and not more than 30 days after a well is put into service following the construction, reconstruction, or rehabilitation. The analysis results shall be submitted to the administrative authority.

B. If the water sample analysis detects presence of bacteria, the disinfection procedure described in BHCC 8.35.290 shall be repeated. [Ord. passed 3/22/2023.]

8.35.310 Abandonment of wells.

A. Abandoned wells are a contamination hazard to the water-bearing formation as well as a physical hazard for people.

B. Plugging Rules. Abandoned wells shall be properly plugged as required in 567 IAC Chapter 39.

C. Waste Disposal Prohibition. Under no circumstances shall abandoned wells be used for the disposal of debris, solid waste, septic tank sludge or effluents, or for any other type of unauthorized disposal of waste materials, or as a receptacle for field tile drainage. [Ord. passed 3/22/2023.]

8.35.320 Closed circuit vertical heat exchangers.

A. These provisions apply to closed circuit vertical heat exchanger construction.

1. Piping used must be 160 psi pressure-rated high-density polyethylene or polybutylene.

2. Connection to piping must use socket fusion or butt fusion joining methods.

3. Piping must be pressure-tested with air or potable water for 15 minutes at a pressure of one and one-half times the system operating pressure after installation in the borehole.

4. The annular space between the vertical heat exchanger piping and the borehole must be grouted as required in BHCC 8.35.120(D) using an approved grouting method and material. Grout shall be placed at least in the top 40 feet. Any confining layers between aquifers shall be replaced with grout. Grouting must be performed within 24 hours of completion of the borehole.

5. Only food-grade or USP-grade propylene glycol or calcium chloride may be used as heat transfer fluid. Any other materials or additives must be NSF-approved for drinking water applications. A permanent sign must be attached to the heat pump specifying that only approved heat transfer fluids may be used.

6. A flow measurement device must be installed on each system.

7. Water make-up lines to the vertical heat exchanger must be protected with a backflow prevention device. [Ord. passed 3/22/2023.]

8.35.330 Inspections.

A. A pre-construction/reconstruction inspection of a proposed well site or reconstruction project shall be conducted by the Environmental Health Officer to ensure compliance with the requirements of this chapter.

B. The certified well contractor shall provide the Environmental Health Officer with reasonable advanced notification prior to the grouting of a newly constructed well.

C. The Environmental Health Officer reserves the right to conduct additional routine inspections of the well construction/reconstruction process. [Ord. passed 3/22/2023.]

8.35.340 Refusal of admittance.

If the Health Officer is refused entry to a property, then the health officer may make a complaint under oath to any magistrate of the county. The magistrate may issue a warrant directing the owner or occupant to allow the Health Officer access to the property for an inspection and directing a peace officer to accompany the Health Officer. [Ord. passed 3/22/2023.]

8.35.350 Notice.

A. When the Health Officer determines that there are reasonable grounds to believe that there has been a violation of any provision of this chapter or any regulation adopted pursuant thereto, they shall give written notice of such alleged violation to the person or persons responsible.

B. Such notice may contain an outline of remedial action which, if taken, will effect compliance with the provisions of this chapter and with regulations adopted pursuant thereto. [Ord. passed 3/22/2023.]

8.35.360 Jurisdiction.

The provisions of this chapter shall apply throughout the County. [Ord. passed 3/22/2023.]

8.35.370 Enforcement.

A. The Environmental Health Officer appointed by the Black Hawk County Board of Health shall have the duty and responsibility of enforcing this chapter.

B. Penalties shall be as provided in this code.

1. A violation of any provision of this chapter or any code, rules, or regulations adopted herein by reference shall constitute a County infraction. Any person committing a County infraction shall, upon conviction, be subject to a civil penalty of not more than $750.00 for each offense, not to exceed $1,000 for each repeat offense. Each day that a violation occurs or is permitted to exist by the violator shall constitute a separate offense.

2. The citation for a county infraction may be served by personal service or by certified mail return receipt requested. The administrative authority shall retain a copy of the citation and one copy shall be sent to the clerk of the district court.

3. A person found guilty of a county infraction is liable for the court costs and fees.

4. In addition to any civil penalty imposed for violation of this article, the court may grant appropriate relief to abate or halt the violation.

5. If a violator willfully fails to pay the civil penalty or violates the terms of any other order imposed by the court, such failure shall constitute contempt.

6. Notwithstanding the provisions of subsections (B)(1) and (B)(4) of this section, anyone who commits a violation of any of the provisions of this chapter may be charged with a simple misdemeanor fine of $65.00 up to the maximum fine of $650.00 and up to 30 days in jail. Each day that a violation occurs or is permitted to exist, following notice of violation, shall constitute a separate offense.

7. The provisions of this chapter shall not preclude the bringing of a civil action by ordinary proceedings to enjoin or abate any nuisance. Any action taken by the local board on such premises shall be charged against the real estate upon which the structure is located and shall be a lien upon such real estate.

C. Nothing herein shall preclude the Department of Natural Resources administration’s right of enforcement under I.C.A. § 455B. [Ord. passed 3/22/2023.]

8.35.380 Appeals.

In the event any person is aggrieved by any order made by the local authority, he/she may appeal to the Board of Health within 20 days of the date of the order, stating in writing the reasons for requesting that the order be rescinded or modified and serving such notice on the Board. The Board of Health shall review the action of the local authority within five days of the service of notice and if reasonable grounds exist, shall modify, withdraw or order compliance with the order. [Ord. passed 3/22/2023.]

8.35.390 Conflict with state law.

This chapter is intended to be consistent with state law. In the event that this chapter conflicts with a state law or a state administrative code rule, the more stringent standards shall be controlling. [Ord. passed 3/22/2023.]

8.35.400 Injunction.

Nothing in this chapter shall prohibit Black Hawk County Board of Health from pursuing injunctive relief or other relief as allowed by law. [Ord. passed 3/22/2023.]

Code reviser’s note: The ordinance passed on 3/22/2023 included two sections numbered 8.35.270 and 8.35.310. These sections and subsequent sections have been renumbered to avoid duplication of numbering.