Chapter 6.70

MONITORING, REPORTING, INSPECTION, AND FACILITY REQUIREMENTS

Sections:

6.70.010 Monitoring and reporting.

6.70.060 Interceptor requirements.

6.70.070 Standard interceptor designs.

6.70.080 Interceptor maintenance.

6.70.090 Liquid waste haulers.

6.70.100 Use of and damage to SAWPA equipment or facilities.

6.70.110 Separation of domestic and industrial waste.

6.70.120 Limitations on wastewater strength.

6.70.140 Pretreatment of industrial wastewaters.

6.70.150 Unauthorized monitoring and pretreatment equipment modifications.

6.70.160 Pretreatment equipment bypass.

6.70.170 Prohibited discharge of recovered pretreatment waste.

6.70.180 Industrial user modifications.

6.70.190 Spill containment systems.

6.70.200 Facility waste management plan.

6.70.210 Notice of potential problems to POTW.

6.70.230 Falsifying information.

6.70.010 Monitoring and reporting.

A. At the direction and discretion of the general manager, any user discharging wastewater directly or indirectly into the Brine Line or tributaries thereto shall be required to install sampling station(s) and measuring device(s) to measure the quality and quantity of wastewater discharged. These measuring devices may include but are not limited to: flow meters and recorders, pH meters and recorders, and electrical conductivity meters and recorders, and process water meters.

B. The sampling station and/or measuring device shall be provided by the user in compliance with this division and all applicable building, plumbing, and construction codes. Monitoring or metering facilities may be required to have a security closure that can be locked with a district or SAWPA lock during sampling and monitoring. Construction shall be completed within a reasonable time frame as required in written notification from the general manager.

C. The general manager shall have the absolute right to install temporarily upon the user’s property such devices as are necessary to conduct wastewater sampling, compliance monitoring or metering operations.

D. No user shall interfere with, delay, resist, or refuse entrance by authorized district or SAWPA personnel or contract employees or authorized OCSD personnel installing wastewater monitoring equipment on the user’s property. Any permanent or temporary obstruction of easy access to the sampling, monitoring, or metering locations shall be immediately removed by the user or property owner at the written or oral request of the general manager and shall not be replaced.

E. The sampling station or measuring devices shall be maintained for continuous sampling or metering. The measuring devices shall be calibrated as often as necessary to ensure accurate measurements according to manufacturer’s specifications. Flow meters shall be calibrated in accordance with WMWDC 6.70.050. All maintenance and calibration work shall be performed at the user’s expense.

F. All users that are required to install and maintain monitoring equipment shall report to SAWPA and the member agency or the contract agency the failure of such equipment within 24 hours. The notification may be accomplished by a telephone call, electronic mail, telefax transmission, personal visit to SAWPA or the member agency or the contract agency, or a hand delivered notification to SAWPA or the member agency or the contract agency. A written report documenting the cause of the failure and the corrective actions taken shall be submitted to the general manager within five business days of discovering the failure.

G. All users that are required to self-monitor shall have all samples collected and analyzed and reported according to 40 CFR 403.12(g) and amendments thereto. Samples shall be collected and analyzed during the period covered by the report and shall be representative of the conditions occurring.

1. Except as indicated in subsections (G)(2) and (3) of this section, the user shall collect wastewater samples using 24-hour time or flow proportional composite samples. Time or flow proportional composite sampling or grab sampling must be representative of the discharge.

2. Samples for oil and grease, temperature, pH, cyanide, total phenols, sulfides and volatile organic compounds must be obtained using grab collection techniques.

3. For sampling required in support of baseline monitoring and 90-day compliance reports, a minimum of four grab samples must be used for pH, cyanide, total phenols, oil and grease, sulfide, and volatile organic compounds for facilities for which historical sampling data does not exist. For facilities for which historical sampling data are available a reduced number of samples may be allowed. For self-monitoring sampling, the user is required to collect the number of grab samples necessary to assess and assure compliance with discharge limits.

4. If a user monitors for regulated pollutants at the appropriate sampling location more frequently than the minimum required, the results of the additional monitoring shall be reported.

H. All pollutant monitoring techniques and analyses, to be submitted as part of a discharge application or self-monitoring report, shall be performed in accordance with the techniques in 40 CFR Part 136 and amendments thereto unless otherwise prescribed in a categorical pretreatment standard or in the user’s wastewater discharge permit.

I. All users that are required to self-monitor shall submit and certify all records of sampling that include the following information and documents:

1. The date, monitoring location, method, and time of monitoring (including the time for each grab whether or not they are later composited into one or more samples) and the name(s) of the person or persons taking the samples;

2. The dates the analyses were performed;

3. Who performed the analyses;

4. The analytical techniques/methods used;

5. The results of such analyses;

6. A copy of the laboratory sample analysis sheet; and

7. A copy of the chain-of-custody form which includes sample collection details such as sample container type, preservation, etc.

These records shall remain available for a period of three years. This period shall automatically be extended for the duration of any litigation concerning the user, or where the user has specifically been notified of a longer retention period by the general manager.

J. All permitted users that take more than one grab sample in a 24-hour period to demonstrate compliance with oil and grease shall comply with the following conditions:

1. No single oil and grease grab sample shall exceed the user’s permitted instantaneous maximum limit for oil and grease at any time.

2. The average result from all individual oil and grease grab samples taken in a 24-hour period shall not exceed the user’s permitted limit for oil and grease.

K. All users that are required to self-monitor shall report pollutant violations in any wastewater sample from an approved monitoring location to the general manager within 24 hours of becoming aware of the violation. The reporting may be accomplished by a telephone call, electronic mail sent to a pre-approved list of electronic mail addresses, telefax transmission, or a meeting with the general manager, a member agency or a contract agency as necessary to comply with the conditions of the wastewater discharge permit. The violation reporting shall contain the date and time of the wastewater sample, the discharge flow rate or volume represented by the sample, a preliminary explanation for the violation(s), proposed corrective action, and the date scheduled for the required resample. Failure to report pollutant violations, as stated, shall constitute a violation of this division and may subject the user to enforcement actions.

L. Any sample collected from a sample box, designated monitoring point or other representative sampling location shall be considered representative of the wastewater discharged to the Brine Line or tributaries thereto.

M. All users that are required to have flow measurement are required to take daily 24-hour readings of their wastewater effluent flow. The user shall report exceedances of their daily permitted flow within 24 hours of discovering the violation. The reporting may be accomplished by a telephone call, electronic mail sent to a pre-approved list of electronic mail addresses, telefax transmission, or a meeting with the general manager or a member or contract agency as necessary to comply with the conditions of the wastewater discharge permit, or a hand delivered notification to the district. The flow exceedance report shall have the total flow, the reason for the flow exceedance, and the name of the person reporting the flow exceedance. This report shall also be in compliance with Chapter 6.65 WMWDC. Failure to report flow exceedances as stated shall constitute a violation of this division and may subject the user to enforcement actions.

N. If sampling performed by a user indicates a violation, the user shall repeat the sampling and analysis and submit the results of the repeat analysis to the district and/or SAWPA within 30 days after becoming aware of the violation. Where the district or SAWPA has performed the sampling and analysis in lieu of the user, the district or SAWPA must perform the repeat sampling and analysis unless it notifies the user of the violation and requires the user to perform the repeat analysis. Resampling is not required if:

1. The district or SAWPA performs sampling at the user’s facility at a frequency of at least once per month; or

2. The district or SAWPA performs sampling at the user’s facility between the time when the initial sampling was conducted and the time when the user or SAWPA receives the results of this sampling.

All resamples shall be obtained and analyzed according to 40 CFR 403.12(g). All laboratory analyses shall be performed by a laboratory certified by the state of California, State Water Resources Control Board, Environmental Laboratory Accreditation Program as being competent to perform the pollutant analyses requested. The laboratory results from this resample and all required forms shall be submitted to the general manager no later than 30 days after the user discovers or becomes aware of the violation. Failure to submit the laboratory results within the 30-day requirement will result in enforcement action. Failure to submit the required report within 45 days of the due date results in a determination of significant noncompliance (SNC) for the user.

O. All users, whose wastewater discharge is monitored by the district or SAWPA, shall be responsible for all resampling requirements contained in subsection N of this section when a pollutant violation is detected. SAWPA shall notify the user of the resampling requirements by a telephone call, electronic mail sent to a pre-approved list of electronic mail addresses, telefax transmission, or personal visit within 24 hours of confirming a pollutant or flow violation.

P. All users that desire to conduct their own wastewater sampling in lieu of a certified contract laboratory shall submit a written plan describing the equipment used, equipment cleaning methodology, employee qualifications and training, sample preservation methods, and chain of custody procedures. The user’s wastewater sampling plan shall be approved by the general manager prior to the implementation of the plan. Any sample collected by a user without an approved plan or from an unapproved laboratory may be considered invalid, and may subject the user to enforcement actions.

Q. All users monitoring their wastewater discharge for pollutants and characteristics required for determining district and/or SAWPA user charges shall submit the sample results in the form of self-monitoring reports as required in their wastewater discharge permit. The frequency of sampling, analysis, and reporting shall be set forth in the user’s wastewater discharge permit. The analyses of the sample pollutants and characteristics shall be at the sole expense of the user. Only sample analyses approved or performed by SAWPA shall be used in the determination of the district and/or SAWPA user charges.

R. SAWPA will meet reporting requirements as specified by 40 CFR Part 3 (Cross-Media Electronic Reporting). Therefore, users that send electronic (digital) documents to SAWPA to satisfy the requirements of this section must register for the system online and submit a signed subscriber agreement to SAWPA for review and approval. An electronic submission shall be deemed to have been properly received by SAWPA when it is received by the electronic system, accessible by SAWPA staff and a confirmation is sent to the signatory making the submission. When the sender receives confirmation and can fully review the submitted materials, report and related data shall be considered received.

S. The user shall submit a written contingency plan that details alternatives to discharging wastewater to the Brine Line during emergency situations in accordance with WMWDC 6.70.200(F) and the user’s approved waste discharge permit.

T. Notification of the Discharge of Hazardous Waste.

1. Discharge of hazardous waste, as defined in 40 CFR 261, is prohibited. Any user that discharges any hazardous waste into the Inland Empire Brine Line shall notify the district, SAWPA and OCSD immediately as required by 40 CFR 403.12(p).

U. A baseline monitoring report (BMR), when required, shall be prepared and submitted per 40 CFR 403.12(b). Completed BMR shall contain a statement of review by an authorized representative of the user and be certified by a qualified professional, indicating whether permit requirements are being met on a consistent basis, and, if not, whether additional operation and maintenance (O and M) and/or additional pretreatment is required for the user to meet the requirements. (Ord. 389 § 5.1, 2018)

6.70.020 Inspection.

A. The general manager shall inspect the facilities of any user using the Brine Line or tributaries thereto to ascertain whether all requirements of this division are being met. Persons on the premises shall allow the general manager, SAWPA authorized personnel, and OCSD authorized personnel ready access at all reasonable times to all parts of the premises for the purpose of inspection, sampling, and records examination.

B. The user shall ensure that there is always a person on site, during normal business hours, knowledgeable of the user’s processes and activities to accompany the duly authorized district and/or SAWPA representative(s) during the inspection.

C. The user shall provide immediate access when an emergency exists, regardless of the hour of the day.

D. All pretreatment equipment shall be immediately accessible at all times for the purpose of inspection. At no time shall any material, debris, obstacles or obstructions be placed in such a manner that will prevent immediate access to the pretreatment equipment or designated monitoring point(s).

E. No person shall interfere with, delay, resist or refuse entrance to the general manager when attempting to inspect any facility involved directly or indirectly with a discharge of wastewater to the Brine Line or tributaries thereto.

F. Where a user has security measures in force which would require proper identification and clearance before entry into the premises, the user shall make all necessary arrangements with the user’s security personnel so that, upon presentation of suitable identification, personnel from SAWPA or duly authorized personnel from district and/or SAWPA or OCSD will be permitted to enter, without delay, for the purpose of performing their specific responsibilities.

G. The user shall make available for copying by the general manager all records required to be kept under the provisions of this division. (Ord. 389 § 5.2, 2018)

6.70.030 Inspection warrants.

If the general manager has been refused access to a building, structure, or property, or any part thereof, with a wastewater discharge to the Brine Line or tributaries thereto, and is able to demonstrate cause to believe that there may be a violation of this division, or that there is a need to inspect or sample the user’s facilities as part of a routine inspection and sampling program of district and/or SAWPA designed to verify compliance with this division or any permit or order issued hereunder, or to protect the overall public health, safety and welfare of the community, then the general manager may seek issuance of an inspection warrant duly issued pursuant to the procedure set forth in Title 13 (commencing with Section 1822.50) of Part 3 of the Code of Civil Procedure. However, in the event of an emergency affecting the public health or safety, an inspection may be performed without consent or the issuance of a warrant. (Ord. 389 § 5.3, 2018)

6.70.040 Record keeping.

All users shall keep records of waste hauling, reclamations, wastewater pretreatment, monitoring device recording charts and calibration reports, effluent flow, and sample analysis data and any documentation associated with best management practices established on the site of the wastewater generation. All these records are subject to inspection and shall be copied as needed. All records must be kept on the site of wastewater generation for a minimum period of three years. The records retention period may be extended beyond three years in the event criminal or civil action is taken or an extensive company history is required. (Ord. 389 § 5.4, 2018)

6.70.050 Flow measurement.

All direct dischargers shall install a continuous monitoring flow meter capable of measuring industrial wastewater discharged to the Brine Line or tributaries thereto. The user shall maintain an effluent flow log sheet and record the effluent flow on a daily basis. The flow measurement device shall conform to standards issued by the general manager. The user shall report to the general manager the type and size of the flow meter. The flow meter shall be equipped with a non-resetting flow totalizer. All flow meters shall be calibrated as often as necessary, but no less frequent than annually. All new meters shall be selected and installed to ensure accuracy of the actual flow discharged within plus or minus two percent as determined at the time of calibration. All existing and replacement meters shall ensure an accuracy of the actual flow discharged within plus or minus five percent. All flow meter installations shall have posted in a conspicuous place, the flow meter’s size, type, totalizer units, and flow multipliers. The user shall immediately report to the general manager any flow meter malfunction or anomaly, and shall not attempt to repair or replace the meter without the general manager’s prior written approval.

A. Flow Measurement System Design and Installation.

1. Design. Design of flow measurement installations shall be performed under the supervision of a California registered professional engineer of suitable discipline competent in this field. Design and construction drawings and calculations shall be stamped with the authorized seal of the supervising professional engineer and signed in accordance with state law, to indicate review and approval of the work. Detailed construction drawings for any new or significantly modified discharge flow measurement system must be submitted for approval prior to any construction. These drawings must show relevant slopes, elevations and locations of piping, types and locations of instrumentation, details of flow measurement elements, estimated flow range (maximum, minimum and average), and details of upstream and downstream piping, structures, and devices which could influence flow conditions. Manufacturer’s calculations, catalog cuts and data sheets must be included with construction drawings for any manufactured equipment to be installed as part of the flow measurement system. Complete rating data and calculations shall be submitted for any engineered flow measurement device.

2. Primary Measurement Devices. Both open channel (flume, weir) and closed-pipe (magnetic) flow measurement systems are acceptable. Magnetic flow meters are preferred for industries that have difficulty maintaining open channel flow measurement. Any flow measurement element that is adversely affected by wastewater characteristics is prohibited. Flow measurement devices shall be installed downstream of final pretreatment facilities and as close as possible to the point of connection with the Brine Line. Above-ground flow measurement installations may require a platform for automatic samplers so that the top of the sampler will be higher than the water level in the primary element. Because it is difficult to set automatic samplers for pressurized closed pipe systems, use of a well-mixed stream through an open channel device (i.e., a sample box) may be required. To function correctly, flumes and weirs must be properly installed in accordance with dimensional specifications. Additionally, flumes must be set level with smooth joints where the influent pipe meets the maintenance access structure or vault channel. To ensure accuracy of an open channel flow measurement system, the upstream channel must be designed to prevent excessive velocity and turbulence, while the downstream channel must be designed to prevent excessive submergence and backflow.

3. Any additional monitoring equipment must not adversely affect hydraulics of the open channel element. All open channel installations below grade must be directly beneath the vault or maintenance access structure access cover to facilitate inspections and field checks. All open channel installations at or above grade must have a staff gauge for accuracy checks. Closed pipe meters must be appropriate for the type of wastewater and range of flow rates, and must be installed to flow full at all times. (Ord. 389 § 5.5, 2018)

6.70.060 Interceptor requirements.

All users required to install a gravity separation interceptor shall comply with the following conditions:

A. All interceptor chambers shall be immediately accessible at all times for the purpose of inspection, sampling, cleaning, and maintenance. The user shall provide a separate ring and cover for each separate interceptor chamber and any additional covers to ensure adequate cleaning capabilities. All rings shall be affixed to the interceptor to ensure a gas and water tight seal. At no time shall any material, debris, obstacles or other obstructions be placed in such a manner that will prevent immediate access to the interceptor.

B. Any interceptor legally and properly installed before August 21, 2007, the effective date of SAWPA Ordinance No. 5, shall be acceptable as an alternative to the interceptor requirements of this division, and SAWPA Ordinance No. 8. The interceptor shall be effective in removing floatable and settleable material and shall be immediately accessible for inspection, sampling, cleaning, and maintenance.

C. All drains and openings connected to an approved gravity separation interceptor shall be equipped with screens or devices which will exclude from the wastewater discharge all material and particles with a cubic dimension greater than one-half of an inch.

D. All gravity separation interceptors shall be equipped with an influent tee extending no more than six inches below the operating fluid level of the interceptor. The interceptor shall also have tees extending to within 12 inches of the bottom at the exit side of each chamber in the interceptor, including the final chamber. In a case where a manufacturer’s engineered interceptor design is contrary to this requirement, the general manager shall review the design and either approve or deny an exemption to this requirement.

E. All interceptors shall be equipped with a sample box or sample wye as determined by the general manager.

F. No user shall install or use any elbows or tees in any interceptor sample box.

G. If the general manager finds that an interceptor is incapable of adequately retaining floatable and settleable material in the wastewater flow, is structurally inadequate or is undersized for the facility, the general manager shall reject such interceptor and declare that the interceptor does not meet the requirements of this section. The user shall thereupon be required to install, at the user’s expense, an interceptor that is acceptable to the general manager. (Ord. 389 § 5.6, 2018)

6.70.070 Standard interceptor designs.

The general manager will maintain a file, available to the public, of suitable designs of gravity separation interceptors. This file will be for informational purposes only and shall not provide or imply any endorsements of any kind. Installation of an interceptor of a design shown in this file, or of any design meeting the size requirements set forth in this division shall not subject the district or SAWPA to any liability for the adequacy of the interceptor under actual conditions of use. The user shall not be relieved of the responsibility for keeping floatable and settleable material out of the Brine Line or tributaries thereto. (Ord. 389 § 5.7, 2018)

6.70.080 Interceptor maintenance.

A. Any user who owns or operates a gravity separation interceptor shall properly maintain the interceptor at all times. The interceptor shall be cleaned as often as necessary to ensure that sediment and floating materials do not accumulate to impair the efficiency of the interceptor and odors do not accumulate which would cause a public nuisance. An interceptor is not considered to be properly maintained if for any reason the interceptor is not in good working condition or if the operational fluid capacity has been reduced by more than 25 percent by the accumulation of floating material, sediment, oils or greases.

B. The use of chemicals or other materials for the emulsification, suspension, or dissolution of oil and grease is prohibited.

C. The use of microbiological agents to metabolize oil and grease or other constituents shall be reviewed for approval on a case-by-case basis. The user shall submit a written request to the general manager for the use of a microbiological agent prior to the use of that agent.

D. When an interceptor is cleaned, the removed sediment, liquid and floating material shall be legally disposed of other than to the Brine Line or tributaries thereto and shall not be reintroduced into the interceptor or discharged into another interceptor at another location not designed and permitted to accept such waste.

E. If the interceptor is not maintained adequately under the conditions of use, the interceptor may be resized and the user shall install one that is effective in accomplishing the intended purpose.

F. The user required to install an interceptor is liable for any failure to properly maintain such interceptor. (Ord. 389 § 5.8, 2018)

6.70.090 Liquid waste haulers.

All liquid waste haulers shall comply with all permitting and disposal procedures as established by this division and pay all applicable fees established by resolution. All liquid waste haulers shall obtain all other applicable permits required by city, county or state agencies. All liquid waste haulers shall also abide by the following requirements and conditions:

A. Liquid waste haulers shall only haul wastewater for generators listed in the permit. Generators shall hold a separate permit issued by SAWPA.

B. If any liquid waste hauler’s load is determined to be hazardous pursuant to applicable federal, state, or local regulations, then the liquid waste hauler shall be required to remain at SAWPA’s Brine Line collection station. The liquid waste hauler shall then make arrangements for the legal disposal of the load. If the liquid waste hauler refuses to remain on site, SAWPA’s general manager shall notify the appropriate law enforcement agency to respond to this violation.

C. Prior to any discharge to a SAWPA Brine Line collection station, all liquid waste manifest forms shall be completed in full, approved and signed by SAWPA’s general manager or his/her designated representative, or otherwise approved by an automated attendant before any load is allowed to be discharged into SAWPA’s Brine Line collection station. Brine Line collection stations with less than full time staffing shall be provided with appropriate and SAWPA-approved automation and procedural safeguards as specified in the disposal site permit.

D. Falsification of any information in any permit application, hauler’s report or manifest, or correspondence by a liquid waste hauler shall be a violation of this division and may result in termination, revocation or suspension of the liquid waste hauler permit and all discharge privileges.

E. All reports and records required to be retained by this division shall be retained for a minimum of three years and shall be made available to SAWPA’s general manager immediately upon request.

F. All liquid waste haulers shall pay all applicable fees and charges. Failure to pay any applicable fee or charge shall be a violation of this division and shall be cause for SAWPA’s general manager to suspend all waste discharge privileges until all applicable fees and charges have been paid.

G. Contents of septic tanks, seepage pits, cesspools, or any other similar receptacles, which contain no industrial waste, shall not be disposed of at SAWPA’s Brine Line collection station.

H. All liquid waste haulers operating within SAWPA’s jurisdiction or tributaries thereto, shall provide documentation as to the origin of the wastes hauled prior to discharging into SAWPA’s Brine Line collection stations. The origin of the waste means the physical address from where the wastes were generated and, if different, the physical address from where the wastes were obtained.

I. If the waste hauled by a liquid waste hauler is found unacceptable for discharge into a SAWPA Brine Line collection station and is not classified as hazardous, then the liquid waste hauler shall dispose of the wastes at a non-SAWPA legal disposal site. The liquid waste hauler shall provide SAWPA with a copy of the waste hauler’s manifest documenting the legal disposal of the rejected wastes within 14 days from the date the waste was rejected. As an alternative, the liquid waste hauler may return the rejected waste to the generator of such rejected wastes for additional pretreatment, and the liquid waste hauler may return to a SAWPA Brine Line collection station or another legal disposal site for discharge. The waste hauler shall also provide SAWPA with a manifest documenting such alternative action. Failure to provide verifiable documentation shall constitute a violation of this division and may result in termination, revocation or suspension of the liquid waste hauler permit and all discharge privileges.

J. No liquid waste hauler shall use any temporary, stationary, or mobile liquid storage device in an attempt to mix or dilute any rejected load in order to achieve compliance.

K. Except as allowed in subsection H of this section, no liquid waste hauler shall dispose of any rejected load into any septic tank, cesspool, seepage pit or similar devices, any grease interceptor or trap, any storm drain, any collection system opening except those authorized in writing by the general manager, or return the rejected load back to the site of origin.

L. Liquid waste haulers are prohibited from discharging domestic waste into the Brine Line or tributaries thereto. No liquid waste hauler shall mix industrial waste and domestic septic wastes in an attempt to discharge the mixture to a SAWPA Brine Line collection station.

M. No liquid waste hauler shall discharge or cause to be discharged any material defined as hazardous by RCRA.

N. Any authorized district or SAWPA employee, authorized representative or contract employee shall have the authority to order the immediate cessation of the discharge from any liquid waste hauler truck into a Brine Line collection station. Such order shall be based on the employee, authorized representative or contract employee’s best professional judgment that said discharge may be in violation of any applicable condition of this division or may otherwise be harmful to the operation of the Brine Line or tributaries thereto, district or SAWPA employees, OCSD’s POTW or its employees.

O. Any liquid waste hauler determined to be in violation of this section may be prohibited from future liquid waste disposal at a Brine Line collection station. (Ord. 389 § 5.9, 2018)

6.70.100 Use of and damage to SAWPA equipment or facilities.

A. No person shall enter, break, damage, destroy, uncover, alter, change, modify, deface or tamper with any temporary or permanent structure, equipment, or appurtenance which is part of SAWPA’s Brine Line without prior written approval by the general manager.

B. Any person who discharges or causes or contributes to the discharge of any wastewater or materials which cause any obstruction, interference, damage, or any other impairment to the Brine Line, OCSD’s POTW, or any other damages, including the imposition of fines or penalties by state, federal or other regulatory agencies against SAWPA, shall be liable to SAWPA for all fines, penalties, damages, legal expenses, attorney’s fees, administrative and overhead costs. An administrative fee of up to 90 percent of SAWPA’s repairs and personnel costs shall be added to these charges at the general manager’s discretion. All charges shall be payable to SAWPA within 30 days of invoicing by SAWPA. (Ord. 389 § 5.10, 2018)

6.70.110 Separation of domestic and industrial waste.

Any user who discharges industrial wastewater to the Brine Line or tributaries thereto shall separate domestic wastewater from all industrial wastewater until the industrial wastewater has passed through all required pretreatment equipment or devices, and the user’s industrial wastewater sample point(s). For existing categorical industrial users which cannot separate the domestic wastes from the industrial wastes prior to a permitted sampling point, the combined wastestream formula shall be applied to determine applicable discharge limitations. Existing industrial users with domestic wastewater in their discharge may be required to install a sampling facility upstream of the domestic wastewater connection(s). (Ord. 389 § 5.11, 2018)

6.70.120 Limitations on wastewater strength.

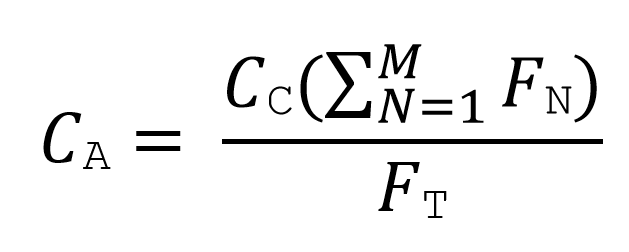

No person shall discharge industrial wastewater into the Brine Line or tributaries thereto unless the wastewater conforms to all of the pollutant limitations and requirements of this division and related SAWPA resolutions. Pollutant limitations shall be revised and adopted by resolution as necessary to ensure compliance with OCSD’s POTW effluent and biosolids reuse. The SAWPA unregulated wastestream correction formula or UWCF may be used to adjust the pollutant limitations to account for the presence of SAWPA unregulated wastestreams.

|

Where: |

CA = |

Adjusted local limit to account for industrial nonprocess wastestream |

|

|

CC = |

Local limit for the pollutant constituent |

|

|

FN = |

Average daily flow for SAWPA industrial process wastestream |

|

|

FT = |

Average daily flow for all wastestreams |

|

|

M = |

Total number of SAWPA industrial process wastestreams |

For categorical industrial users, the following options exist:

A. Where a categorical pretreatment standard is expressed in terms of either the mass or the concentration of a pollutant in wastewater, the general manager may impose equivalent concentration or mass limits in accordance with 40 CFR 403.6(c).

B. When wastewater subject to a categorical pretreatment standard is mixed with wastewater not regulated by the same standard, the general manager shall impose an alternate limit using the combined wastestream formula, or a flow-weighted calculation, as appropriate.

C. A variance from a categorical pretreatment standard may be issued if the user can prove, pursuant to the procedural and substantive provisions in 40 CFR 403.13, that factors relating to its discharge are fundamentally different from the factors considered by the EPA when developing the categorical pretreatment standard. (Ord. 389 § 5.12, 2018)

6.70.130 Local limits.

The general manager shall implement pollutant limitations developed as local limits by OCSD pursuant to 40 CFR 403.5(c) and 403.8(f)(4) and amendments thereto, and as local limits and best management practices to protect the operation of the Brine Line and prevent SSOs. These limitations are necessary to assure compliance with the OCSD’s NPDES permit, including the prohibition against pass through of any pollutants that cause a violation of the permit or cause interference with the POTW, and compliance with SWRCB adopted Order No. 2006-003, a general waste discharge requirement (WDR) for all publicly owned sanitary sewer collection systems in California with more than one mile of sewer pipe. Customer specific allocations at current POTW loadings may be created for public health facilities providing a lifesaving service or procedure so long as the pollutant discharged will not contribute to pass through, interference or other violation of the OCSD’s NPDES permit. These pollutant limitations shall be continually developed as necessary and shall be adopted by resolution. Specific pollutant limits shall not be developed and enforced without individual public notice to affected persons or users. (Ord. 389 § 5.13, 2018)

6.70.140 Pretreatment of industrial wastewaters.

All users shall:

A. Provide wastewater pretreatment, as required, to comply with this division and any applicable SAWPA resolution.

B. Whenever deemed necessary, the general manager may require users to restrict their wastewater discharge, relocate and/or consolidate points of discharge, separate domestic wastestreams from industrial wastestreams, and other such conditions as may be necessary to protect OCSD’s POTW and determine the user’s compliance with the requirements of this division.

C. Notify the general manager of any pretreatment equipment failure within 24 hours of discovering the failure. The notification may be made by a telephone call, electronic mail sent to a pre-approved list of electronic mail addresses, telefax transmission, or a meeting with the general manager or a member agency or a contract agency as necessary to comply with the conditions of the wastewater discharge permit. (Ord. 389 § 5.14, 2018)

6.70.150 Unauthorized monitoring and pretreatment equipment modifications.

No user shall knowingly falsify, tamper with, or render inaccurate any monitoring device or any pretreatment equipment or device. Such falsification, tampering, or inaccuracy will be considered a violation of this division and will subject the user to enforcement actions. (Ord. 389 § 5.15, 2018)

6.70.160 Pretreatment equipment bypass.

No user shall bypass any pretreatment equipment or device unless the bypass is necessary to prevent loss of life, personal injury, and severe property damage or when no feasible alternative exists. The user may allow the bypass to occur provided that it does not cause pollutant limitation violations and is necessary to perform essential maintenance to ensure adequate operation of the pretreatment equipment or devices. The general manager may approve an anticipated bypass, after considering its adverse effects, if the general manager determines that it will meet the three conditions listed in 40 CFR 403.17(d)(1). Notification of the bypass shall comply with the following conditions:

A. Anticipated Bypass. The user shall submit a written notice to the general manager at least 10 days before the date of the scheduled bypass.

B. Unanticipated Bypass. The user shall notify the general manager immediately upon learning that any pretreatment equipment or device has been bypassed. The user shall submit a written report to the general manager within five working days. The report shall include:

1. A description of the bypass, the cause of the bypass, and the duration of the bypass;

2. If the bypass was corrected; and

3. The actions taken or proposed to reduce or prevent a recurrence of the bypass. (Ord. 389 § 5.16, 2018)

6.70.170 Prohibited discharge of recovered pretreatment waste.

No person shall discharge waste recovered from pretreatment equipment, systems, or devices into the Brine Line or tributaries thereto without authorization and permits from SAWPA and/or other regulatory agencies having jurisdiction over the discharge of the waste. All recovered pretreatment waste shall be disposed of in accordance with all applicable federal, state, county, and local laws and regulations. (Ord. 389 § 5.17, 2018)

6.70.180 Industrial user modifications.

All permitted industrial users shall report proposed changes in their operations to the general manager for review and approval 30 days prior to initiation of the changes. The reporting shall be done in writing from the authorized representative of the permitted industrial user. For the purposes of this section “changes” shall include any of the following:

A. A sustained 20 percent increase or decrease in the industrial wastewater flow discharged or in production capacity.

B. Additions, deletions or changes to processes or equipment.

C. Experimentation with new processes and/or equipment that will affect the quantity or quality of the wastewater discharged. (Ord. 389 § 5.18, 2018)

6.70.190 Spill containment systems.

Spill containment systems, as may be required, shall conform to requirements established by the general manager. These requirements may include, but not be limited to, the following:

A. No user shall operate a spill containment system that allows incompatible substances to mix and thereby creating a hazardous or toxic substance in the event of a failure of one or more containers.

B. Spill containment systems shall consist of a system of dikes, walls, barriers, berms, or other devices designed to contain spillage of the liquid contents of containers.

C. Spill containment systems shall be constructed of materials that are impermeable and nonreactive to the liquids being contained.

D. Spill containment systems shall conform to local regulations and policies as to percent containment, container type, size, outdoor covering, and the length of time spilled material may remain in the spill containment system.

E. At no time shall a user use a spill containment system for the storage of waste other than from a spill. (Ord. 389 § 5.19, 2018)

6.70.200 Facility waste management plan.

All permitted industrial users shall be required to develop and maintain a facility waste management plan (FWMP). The FWMP may consist of the following documents:

A. Toxic Organic Management Plan (TOMP). At SAWPA’s discretion categorical industrial users may be permitted to submit a TOMP in lieu of required pollutant monitoring. SAWPA reserves the right to require total toxic organic monitoring of all users allowed to submit a TOMP.

B. Slug Discharge Prevention Control Plan (SDPCP). A SDPCP may be required of industrial users as determined by the general manager. Considerations to determine the need for a SDPCP include the use of batch discharges to dispose of wastewater, stored chemicals or materials, or the potential for a slug discharge which, if discharged to the Brine Line or tributaries thereto, would violate any of the prohibited discharge requirements of this division. A SDPCP showing facilities and operation procedures to provide this protection shall be submitted to the general manager for review and approval before implementation.

Any user required to develop and implement an SDPCP shall submit an SDPCP which addresses, at a minimum the following:

1. Description of discharge practices, including nonroutine batch discharges;

2. Description of stored chemicals;

3. Procedures for immediately notifying SAWPA of any accidental or slug discharge. Such notification must also be given for any discharge which would violate any of the standards set forth in this division and any local, state or federal regulations; and

4. Procedures to prevent adverse impact from any accidental or slug discharge. Such procedures include, but are not limited to, inspection and maintenance of storage areas, handling and transfer of materials, loading and unloading operations, control of plant site runoff, worker training, building of containment structures or equipment, measures for containing toxic organic chemicals (including solvents), and/or measures and equipment for emergency response.

Each user shall implement its SDPCP as submitted or modified after such plan has been reviewed and approved by the general manager. Review and approval of such plans and operations procedures by the general manager shall not relieve the user from the responsibility to modify its facility as necessary to meet the requirements of this division.

C. Pretreatment Systems Operations and Maintenance Manual. A pretreatment systems operations and maintenance manual shall be maintained on site by all industrial users operating and maintaining pretreatment equipment for the removal of pollutants from wastewater. The general manager may require the industrial user to submit the manual.

D. Hazardous Materials and Hazardous Waste Management Plan. A hazardous materials and hazardous waste management plan is required of all industrial users that use or possess hazardous materials or generate hazardous waste. A city or county fire department required business emergency plan may be substituted for this management plan.

E. Waste Minimization/Pollution Prevention Plan (WM/PPP).

1. A waste minimization/pollution prevention plan (WM/PPP) is required of any industrial user:

a. For whom the general manager has determined such WM/PPP is necessary to achieve a water quality objective;

b. Determined by the state or regional board to be a chronic violator, and the state or regional board or SAWPA’s general manager determines that a WM/PPP is necessary; or

c. That significantly contributes, or has the potential to significantly contribute, to the creation of a toxic hot spot as defined in Water Code Section 13391.5.

2. A WM/PPP required of an industrial user shall include all of the following:

a. An analysis of one or more of the pollutants, as directed by the state board, regional board, or the district and/or SAWPA, that the user discharges to the Brine Line or tributaries thereto, description of the sources of the pollutants, and a comprehensive review of the processes used by the user that result in the generation and discharge of the pollutants.

b. An analysis of the potential for pollution prevention to reduce the generation of the pollutants, including the application of innovative and alternative technologies and any adverse environmental impacts resulting from the use of those methods.

c. A detailed description of the tasks and time schedules required to investigate and implement various elements of pollution prevention techniques.

d. A statement of the user’s pollution prevention goals and strategies, including priorities for short-term and long-term action.

e. A description of the user’s existing pollution prevention methods.

f. A statement that the user’s existing and planned pollution prevention strategies do not constitute cross media pollution transfers unless clear environmental benefits of such an approach are identified to the satisfaction of SAWPA and information that supports that statement.

g. Proof of compliance with the Hazardous Waste Source Reduction and Management Review Act of 1989 (Article 11.9 (commencing with Section 25244.12) of Chapter 6.5 of Division 20 of the Health and Safety Code) if the user is also subject to that act.

h. An analysis, to the extent feasible, of the relative costs and benefits of the possible pollution prevention activities.

i. A specification of, and rationale for, the technically feasible and economically practicable pollution prevention measures selected by the user for implementation.

3. Any user who fails to complete a WM/PPP required by the district and/or SAWPA or the state or regional board, submits a plan that does not comply with this section, or fails to implement a plan required by the district and/or SAWPA or the state or regional board, shall be liable to the district and/or SAWPA for any civil penalty assessed administratively by the district and/or SAWPA or by a court in accordance with this division, including any attorneys fees incurred by the district and/or SAWPA.

F. Emergency Contact List and Contingency Plan. All users are required to submit, and retain a copy on site, a contingency plan that details the actions that will be taken in the event of an emergency or other event that causes SAWPA or the control authority to shut down the Brine Line. Said plan shall include, but is not limited to the following:

1. A list of names and telephone numbers of emergency contacts that can be reached 24 hours a day (shall be provided to SAWPA semi-annually in January and July).

2. A written plan (updated and provided to SAWPA annually in January) that describes all available alternatives to discharging to the Brine Line, including on-site storage, hauling, ceasing the discharge, or directing all wastewater flows to a local POTW. (Ord. 389 § 5.20, 2018)

6.70.210 Notice of potential problems to POTW.

All users shall immediately notify SAWPA of all wastewater discharges that could cause a problem at OCSD’s POTW or in the Brine Line or tributaries thereto, including any slug loadings of any material. Wastewater discharges that may cause a problem at OCSD’s POTW or the Brine Line or tributaries thereto include, but are not limited to, acids, alkalis, oils, greases, high strength organic waste, hazardous materials and waste, colored wastes, and batch discharges. All users shall provide the general manager, within five business days from the incident, a written report detailing the cause of the discharge and the corrective actions taken to prevent a recurrence. A notice shall be permanently posted at a prominent location at the user’s facility advising employees and listing the emergency call contact name and numbers in the event of a wastewater discharge that could cause a potential problem. Employees who could cause or become aware of such a discharge shall be advised of the emergency notification procedure. (Ord. 389 § 5.21, 2018)

6.70.220 Written responses.

All users required to provide written response to any correspondence, order, or notice from the general manager, shall do so in accordance with the date specified in the correspondence, order, or notice. Failure to provide the written response by the date requested shall constitute a violation of this division and may subject the user to enforcement actions. (Ord. 389 § 5.22, 2018)

6.70.230 Falsifying information.

Any user who knowingly makes any false statement, representation, or certification in any record, report, correspondence, or other document submitted or required to be maintained under this division, including monitoring reports and records, or reports of compliance or noncompliance shall be in violation of this division and may subject the user to enforcement actions. (Ord. 389 § 5.23, 2018)