Chapter 4

TRANSPORTATION

Chapter 4

4A GENERAL STANDARDS

4A.010 General

4B STREETS

4B.010 General

4B.020 Design Standards

4B.030 Functional Classification

4B.035 Commercial Collectors

4B.040 Naming

4B.050 Signing and Striping

4B.060 Right-of-Way

4B.070 Private Streets

4B.080 Streetside (Frontage) Improvements

4B.085 StreetSide (Frontage) Improvements West Bay Drive

4B.090 Streetside (Frontage) Improvements Boulevard Road (Standard Drawing 4-2G8)

4B.095 Streetside (Frontage) Improvements East Downtown

4B.110 Half Street

4B.120 Medians

4B.130 Intersections

4B.140 Driveways

4B.150 Sight Obstructions at Intersections

4B.160 Surfacing Requirements

4B.170 Temporary Street Patching

4B.175 Pavement Restoration

4B.180 Trench Backfill

4B.190 Surveying and Staking

4B.195 Utility Coordination

4B.200 Testing

4B.210 Traffic Calming Devices

4C SIDEWALKS AND CURBS

4C.020 Design Standards

4C.030 Sidewalks

4C.040 Curb or Curb and Gutter

4C.050 Curb Ramps

4C.060 Staking

4C.070 Parking Bulb-outs

4C.071 Pedestrian Bulb-outs

4D BIKEWAYS

4D.020 Design Standards

4D.030 Staking and Testing

4E TRAILS OR SHARED-USE PATHS

4E.010 Design Standards

4E.020 Pathway Illumination

4F ILLUMINATION

4F.010 General

4F.020 Design Standards

4F.030 Technical Requirements for Streetlight Construction

4F.040 Staking

4F.050 Testing

4G SIGNALS

4G.010 General

4G.020 Design Standards

4G.030 Induction Loops

4G.040 Staking

4G.050 Testing

4G.060 Checkout Procedures

4H MISCELLANEOUS STREETSIDE FEATURES

4H.010 General

4H.020 Design Standards

4H.030 Surveying and Staking

4H.040 Testing

4H.050 Survey Monuments

4H.060 Bus Stops and Amenities

4H.070 Mailboxes

4H.080 Guardrails

4H.090 Retaining Walls

4H.100 Street Trees

4H.110 Parking Lots

4H.120 Parking Meters

4H.130 Crosswalks

4I ACCESS POINTS AND INTERSECTION CRITERIA

4I.010 General

4I.020 Applicability

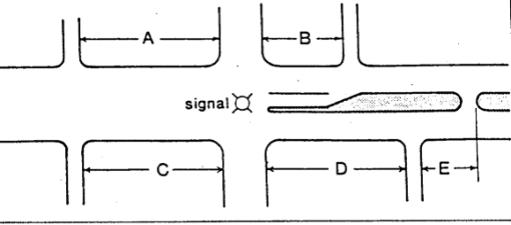

4I.030 Methods of Measurements

4I.040 Spacing of Access Points, Same Side of Street

4I.050 Alignment of Offset of Cross-Street Access Points

4I.060 Corner Clearance from Intersections

4I.070 Number of Access Points

4I.080 Access Location Based on Street Class

4I.090 Combined or Shared Access

4I.100 Direction of Driveways (One-Way or Two-Way)

4I.110 Adjustment for Street Gradient

4I.120 Drive-Through Windows

4I.130 Monitoring and Enforcement

4I.140 Design of Access Points and Driveways

Appendix 1: List of Standard Drawings

Appendix 2: Index of Tables

Appendix 3: Monument Preservation Documentation Letter

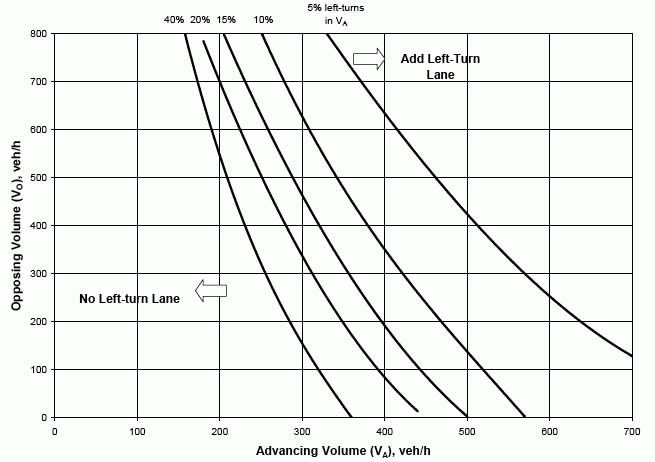

Appendix 4: Downtown Boundaries

Appendix 5: Transportation Related Special Provisions

Appendix 6: Pervious Concrete Sidewalk Construction Standards

Appendix 7: Traffic Impact Analysis (TIA) Guidelines for New Developments

4A GENERAL STANDARDS

4A.010 General

The intent of this chapter is to encourage the uniform development of an integrated and accessible public street system that will support present and future multi-modal transportation.

Through the implementation of these standards, streets are built as transportation facilities as well as public spaces, contributing positively to the character of an area. These standards help create an efficient multi-modal transportation system with minimal environmental impact to the community.

These standards balance the safety and mobility of motor vehicles, bicyclists, pedestrians and transit riders. The features in the standards are intended to: maintain safe motor vehicle speeds through narrow street widths and street edge features for friction; provide safe pedestrian crossings through narrow lane widths, crossing islands, and curb bulb-outs; provide inviting space for pedestrians on wide sidewalks with buffers from motor vehicle traffic; provide adequate width, signs and markings for safe on-street bicycle travel, and; create inviting public space through landscaping and other street edge treatments.

This chapter provides minimum development standards supplementing the applicable standards as set forth.

Deviations as defined in Chapter 1 shall be considered by the City Engineer as outlined in Chapter 1, Section 1.050. A request for deviation increasing the 10' travel lane width for Arterial and Major Collector streets shall be based upon the following criteria:

• High frequency transit route as defined by 15 minute transit service frequency on any given day.

• High frequency truck traffic where trucks compose 5 percent or more of the total daily traffic.

• The roadway alignment includes a unique curve of 200 foot radius or less.

• The geometry of the roadway includes a skewed intersection.

4B STREETS

4B.010 General

Design and construction of City streets shall meet the standards in this and other relevant sections of this Chapter. Table 1 lists all Arterials and Major Collectors, and the number of lanes required for each street section listed. Table 2 summarizes the Street Design Standards and Table 3 summarizes other Street Characteristics to be considered and/or addressed.

4B.020 Design Standards

The design of streets and roads will depend upon their type and usage. The design elements of city streets will conform to City standards as set forth herein, to safely and uniformly accommodate maximum anticipated loading conditions.

The layout of streets will provide for the continuation of existing streets in adjoining subdivisions or of their proper projection when adjoining property is not subdivided.

A. Alignment. Alignment of major arterials, minor arterials, and collectors will conform as nearly as possible with that shown in the Comprehensive Plan.

B. Grade. Street grade should conform closely to the natural contour of the land. In some cases a different grade may be required by the City Engineer. The minimum allowable grade will be 0.5 percent. The maximum allowable grade will be 8 to 15 percent, depending upon the street classification.

C. Width. The pavement and right-of-way width depend upon the street classification. Table 2, Street Design Standards, shows the minimum widths allowed.

Street widths will be measured as shown on Standard Drawings for each street classification.

D. The General Notes for Street Construction listed on Drawing 3-1 shall be included on any plans dealing with street, sidewalk and/or pathway design as applicable.

E. Low Impact Development. As part of meeting the DDECM’s LID-related requirements, bioretention swales may be allowed under certain conditions outlined in the DDECM, as amended and updated. Standard street sections for those street classifications allowing bioretention swales are indicated in the Standard Drawings that have a drawing number ending in “-LID”. Swale details, including planting requirements, can be found in Chapter 5 of the EDDS

4B.030 Functional Classification

City streets are divided into Arterial, Major Collector, Neighborhood Collector, and Local Access street classifications. The City Council has the authority to classify or reclassify all streets, in accordance with regional transportation needs and the functional use each serves. Definitions for each of these street classifications can be found in section 2.020 of these Standards.

4B.035 Commercial Collectors

The Commercial Collector Street standard in Table 2 apply to (1) all streets in the Downtown area (see Appendix 4), as well as commercially-zoned areas of the City that are not Arterials. Commercial Collector Streets shall be constructed or reconstructed to the Commercial Collector street standard, as detailed in Table 2 and Standard Drawings 4-2D, 4-2E, 4-2E-LID1, 4-2E-LID2 and 4-2G10. Commercial Collector streets shall include bike lanes as they apply to Major Collectors and Neighborhood Collectors (refer to Section 4D, Bikeways, for guidance.

|

Region Section |

Street Name |

From |

To |

Class |

Required Lanes (1) |

Street Classification (2) |

|---|---|---|---|---|---|---|

|

DT |

4th Avenue |

Olympic Way |

Water Street |

Arterial |

4/5 |

Existing Arterial |

|

DT |

4th Avenue |

Water Street |

Chestnut Street |

Arterial |

2 |

Existing Arterial |

|

NS |

4th Avenue |

Chestnut Street |

Pacific Avenue |

Arterial |

3 |

Existing Arterial |

|

NS |

4th Avenue |

Pacific Avenue |

Phoenix Street |

Arterial |

5 |

Existing Arterial |

|

DT |

14th Avenue |

Capitol Way |

I-5 |

Arterial |

4/5 |

Existing Arterial |

|

DT |

Adams Street |

State Avenue |

8th Street |

Arterial |

2 |

Existing Arterial |

|

WS |

Black Lake Boulevard |

US 101 |

21st Avenue |

Arterial |

5 |

Existing Arterial |

|

WS |

Black Lake Boulevard |

21st Avenue |

South City Limits |

Arterial |

4/5 |

Existing Arterial |

|

WS |

Black Lake Boulevard |

Cooper Point Road |

US 101 |

Arterial |

5 |

Widening of Existing Arterial |

|

WS |

Black Lake Boulevard |

4th Avenue |

Cooper Point Road |

Arterial |

4/5 |

Existing Arterial |

|

DT |

Boston Harbor Road |

North City Limits |

Ames Road |

Arterial |

2 |

Existing Major Arterial |

|

SS |

Capitol Boulevard |

Capital Way |

Carlyon Avenue |

Arterial |

4 |

Existing Arterial |

|

DT |

Capitol Way |

Corky Avenue |

Capitol Boulevard |

Arterial |

4 |

Existing Arterial |

|

WS |

Cooper Point Road |

Conger Avenue |

Evergreen Park Drive |

Arterial |

5 |

Existing Arterial |

|

WS |

Cooper Point Road |

Evergreen Park Drive |

US 101 |

Arterial |

5 |

Widening of Existing Arterial |

|

WS |

Cooper Point Road |

28th Street |

Conger Avenue |

Arterial |

2/3 |

Widening of Existing Arterial |

|

WS |

Division Street |

14th Avenue |

Garfield Avenue |

Arterial |

2/3 |

Existing Arterial |

|

WS |

Division Street |

Garfield Avenue |

4th Avenue |

Arterial |

4/5 |

Existing Arterial |

|

NS |

East Bay Drive |

Ames Road |

San Francisco Avenue |

Arterial |

2/3 |

Existing Arterial |

|

NS |

East Bay Drive |

San Francisco Avenue |

State Avenue |

Arterial |

3 |

Existing Arterial |

|

WS |

Harrison Avenue |

Cushing Street |

Olympic Way |

Arterial |

4/5 |

Existing Arterial |

|

WS |

Harrison Avenue |

Cooper Point Road |

Cushing Street |

Arterial |

4/5 |

Existing Arterial |

|

WS |

Harrison Avenue |

West City Limits |

Cooper Point Road |

Arterial |

4/5 |

Widening of Existing Arterial |

|

DT |

Henderson Boulevard |

Plum Street |

I-5 |

Arterial |

4/5 |

Existing Arterial |

|

SS |

Henderson Boulevard |

I-5 |

North Street |

Arterial |

2/3 |

Existing Arterial |

|

DT |

Jefferson Street |

8th Avenue |

Maple Park Avenue |

Arterial |

4/5 |

Existing Arterial |

|

NE |

Martin Way |

Phoenix Street |

Devoe Street |

Arterial |

5 |

Existing Arterial /Future Turn Lane |

|

NE |

Martin Way |

Devoe Street |

Lilly Road |

Arterial |

4 |

Addition RW for Median Island |

|

NE |

Martin Way |

Lilly Road |

College Street |

Arterial |

5 |

|

|

WS |

Mud Bay Road |

West UGB |

West City Limits |

Arterial |

4/5 |

Widening of Existing Arterial |

|

WS |

Olympic Way |

4th Avenue Bridge |

Harrison Avenue |

Arterial |

4 |

Existing Arterial |

|

NE |

Pacific Avenue |

State Avenue |

I-5 Overpass |

Arterial |

4/5 |

Existing Arterial |

|

SS |

Pacific Avenue |

I-5 |

East City Limits |

Arterial |

4/5 |

Existing Arterial |

|

SS |

Pacific Avenue |

East City Limits |

East UGB |

Arterial |

4/5 |

Existing Arterial |

|

DT |

Plum Street |

State Avenue |

Henderson Boulevard |

Arterial |

4/5 |

(1) Existing Arterial |

|

NE |

Sleater-Kinney Road |

I-5 |

Martin Way |

Arterial |

4/5 |

Existing Arterial |

|

DT |

State Avenue |

Wilson Street |

Water Street |

Arterial |

2 |

Existing Arterial, Potential HOV |

|

DT |

Union Avenue |

Capitol Way |

Plum Street |

Arterial |

4/5 |

Existing Arterial |

|

DT |

Union Avenue |

Plum Street |

Eastside Street |

Arterial |

4/5 |

Existing Arterial |

|

DT |

Water Street |

State Avenue |

4th Avenue |

Arterial |

3 |

Existing Arterial |

|

WS |

Yauger Way Extension |

SR 101/Black Lake Boulevard |

Capital Mall Drive |

Arterial |

2/3 |

Future Arterial |

|

SS |

Yelm Highway |

Henderson Boulevard |

Rich Road |

Arterial |

4/5 |

Existing Arterial |

|

WS |

4th Avenue |

Kenyon Street |

Olympic Way |

Major Collector |

2 |

Existing Major Collector |

|

DT |

5th Avenue |

4th Avenue/Olympic Way |

Water Street |

Major Collector |

4 |

Existing Major Collector |

|

NS |

5th Avenue |

Water Street |

Eastside Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

7th Avenue |

Kaiser Road |

McPhee Road |

Major Collector |

2/3 |

Existing Major Collector |

|

DT |

8th Avenue |

Capitol Way |

Eastside Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

9th Avenue |

Black Lake Boulevard |

Decatur Road |

Major Collector |

2/3 |

Existing Major Collector |

|

DT |

11th Avenue |

Capitol Way |

Jefferson Street |

Major Collector |

2 |

Existing Major Collector w/ Center Median |

|

NE |

12th Avenue |

Wilson Street |

Fenske Drive |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

12th Avenue |

South Bay Road |

City Limits |

Major Collector |

2/3 |

Additional RW for New Major Collector |

|

NE |

12th Avenue |

PSP Hospital |

Sleater-Kinney Road |

Major Collector |

2/3 |

Additional RW for New Major Collector |

|

WS |

14th Avenue |

Kaiser Road |

Division Street |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

14th Avenue |

Elizabeth Street |

East City Limits |

Major Collector |

2/3 |

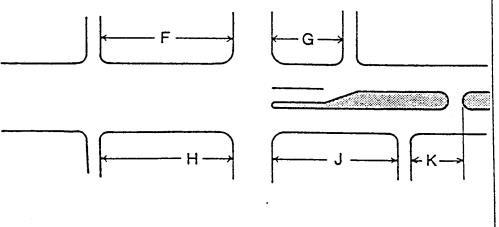

Existing Major Collector/Future Left-Turn Needs |

|

SS |

18th Avenue |

Wilson Street |

Elizabeth Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

20th Avenue |

Road Sixty-Five |

Crestline Boulevard |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

20th Avenue |

Kaiser Road |

Road Sixty-Five |

Major Collector |

2/3 |

Future Major Collector |

|

WS |

21st Avenue |

Black Lake Boulevard |

R.W. Johnson Boulevard |

Major Collector |

2/3 |

(2) Existing Major Collector |

|

SS |

22nd Avenue |

Eastside Street |

Boulevard Road |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

26th Avenue |

South Bay Road |

Pleasant Glade Road |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

26th Avenue |

Gull Harbor Road |

South Bay Road |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

27th Avenue |

Wiggins Road |

Hoffman Road |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

28th Avenue |

Division Street |

West UGB |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Ames Road |

East Bay Drive |

North City Limits |

Major Collector |

2 |

Existing Major Collector |

|

NE |

Bethel Street |

26th Avenue |

San Francisco Avenue |

Major Collector |

2 |

Existing Major Collector |

|

WS |

Birch/Bing Street |

Harrison Avenue |

4th Avenue |

Major Collector |

2/3 |

Future Major Collector |

|

NE, SS |

Boulevard Road |

Pacific Avenue |

Yelm Highway |

Major Collector |

2/3 |

Major Collector Medians (See Table 5) |

|

SS |

Cain Road |

22nd Avenue |

Log Cabin Road |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Capital Mall Drive |

McPhee Road |

Black Lake Boulevard |

Major Collector |

4 |

Existing Major Collector |

|

SS |

Carlyon Avenue |

Capitol Boulevard |

Henderson Boulevard |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Carriage Loop |

Carriage Street |

Carriage Drive |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Carriage Street |

Cooper Point Road |

Carriage Drive |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Caton Way |

Cooper Point Road |

Decatur Street (at south end of trail) |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Central Street |

Bigelow Avenue |

11th Avenue |

Major Collector |

2 |

Existing Major Collector |

|

WS |

Conger Avenue |

Harrison Avenue |

Cooper Point Road |

Major Collector |

2/3 |

Future Major Collector |

|

WS |

Conger Avenue |

Cooper Point Road |

Division Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Cooper Point Road |

North UGB |

28th Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Crestline Boulevard |

Elliot Avenue |

Raft Avenue |

Major Collector |

2 |

Existing Major Collector |

|

DT |

D Avenue |

Capitol Way |

Franklin Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Decatur Street |

Harrison Avenue |

9th Avenue |

Major Collector |

2 |

Existing Major Collector |

|

WS |

Decatur Street |

9th Avenue |

1700 Block |

Major Collector |

2 |

Existing Major Collector |

|

WS |

Deschutes Parkway |

5th Avenue |

South City Limits |

Major Collector |

2/3 |

Major Collector |

|

WS |

Division Street |

28th Avenue |

14th Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

Eastside Street |

State Avenue |

22nd Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

Elizabeth Street |

18th Avenue |

14th Avenue |

Major Collector |

3 |

Existing Major Collector |

|

NE |

Ensign Road |

Martin Way |

Lilly Road |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Ensign Road |

Pacific Avenue |

Martin Way |

Major Collector |

2/3 |

Future Major Collector |

|

SS |

Eskridge Boulevard |

O’Farrell Avenue |

Cain Road |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Evergreen Park Drive |

Cooper Point Road |

Lakeridge Drive |

Major Collector |

2/3 |

Future Major Collector |

|

NS |

Fir Street |

Legion Way |

Pine Street |

Major Collector |

2 |

Future Major Collector |

|

SS |

Fones Road |

1400 Block Fones Road |

18th Avenue |

Major Collector |

3 |

Widening of Existing Major Collector |

|

SS |

Fones Road |

Pacific Avenue |

1400 Block Fones Road |

Major Collector |

4/5 |

Widening of Existing Major Collector |

|

NE |

Friendly Grove Road |

North UGB |

26th Avenue |

Major Collector |

2 |

Existing Major Collector |

|

NE |

Friendly Grove Road |

26th Avenue |

Miller Avenue |

Major Collector |

2 |

Existing Major Collector |

|

NE |

Gull Harbor Road |

North UGB |

North City Limits |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

Henderson Boulevard |

North Street |

Yelm Highway |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

Herman Road |

Wiggins Road |

East City Limits |

Major Collector |

2/3 |

Future Major Collector Boulevard |

|

SS |

Hoffman Road |

18th Avenue |

Morse-Merrymann Road |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

Hoffman Road |

Morse-Merryman Road |

Log Cabin Road Connection |

Major Collector |

2/3 |

Future Major Collector |

|

SS |

Hoffman Road Realignment |

Fones Road/Hoffman Road |

Fones Road/Elizabeth Avenue |

Major Collector |

2/3 |

Future Major Collector |

|

WS |

Kaiser Road |

16th Lane SW |

Black Lake Boulevard |

Major Collector |

2/3 |

Future Major Collector |

|

WS |

Kaiser Road |

Evergreen College Parkway |

Cooper Point Road |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Kaiser Road |

North UGB |

16th Lane SW |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Kenyon Street |

Harrison Avenue |

4th Avenue |

Major Collector |

4 |

Existing Major Collector |

|

WS |

Lakeridge Drive |

Deschutes Parkway |

Evergreen Park Drive |

Major Collector |

2/3 |

Future Major Collector |

|

DT |

Legion Way |

Water Street |

Plum Street |

Major Collector |

2/3 |

Existing Major Collector |

|

NS |

Legion Way |

Plum Street |

Fir Street |

Major Collector |

2 |

Existing Major Collector |

|

NE |

Lilly Road |

North UGB |

15th Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Lilly Road |

15th Avenue |

Martin Way |

Major Collector |

4 |

Existing Major Collector |

|

NE |

Lilly Road |

Martin Way |

I-5 Overpass |

Major Collector |

4/5 |

Existing Major Collector |

|

SS |

Lilly Road |

I-5 |

Pacific Avenue |

Major Collector |

4/5 |

Existing Major Collector |

|

SS |

Log Cabin Road |

Cain Road |

Boulevard Road |

Major Collector |

2/3 |

Existing Major Collector |

|

SS |

Log Cabin Road Connections |

Boulevard Road |

Major Collector |

2/3 |

Future Major Collector Boulevard |

|

|

WS |

McPhee Road |

Harrison Avenue |

7th Avenue / Capital Mall |

Major Collector |

2/3 |

Existing Major Collector |

|

DT |

Marine Drive |

Market Street |

Olympia Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

DT |

Market Street |

Capitol Way |

Marine Drive |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Miller Avenue |

Bethel Street |

Friendly Grove Road |

Major Collector |

2 |

Existing Major Collector |

|

SS |

Morse-Merryman Road |

Boulevard Road |

Wiggins Road |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Mottman Road |

R.W. Johnson Boulevard |

Crosby Boulevard |

Major Collector |

2/3 |

Existing Major Collector/Future Left-Turn Needs |

|

SS |

North Street |

West City Limits |

Cain Road |

Major Collector |

2/3 |

Existing Major Collector/Future Left-Turn Needs |

|

SS |

O’Farrell Avenue |

Capitol Boulevard |

Eskridge Boulevard |

Major Collector |

2 |

Existing Major Collector |

|

NS |

Olympia Avenue |

Jefferson Street |

East Bay Drive |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Pattison Street |

Martin Way |

Pacific Avenue |

Major Collector |

2/3 |

Future Major Collector |

|

NS |

Phoenix Street |

South Bay Road |

Pacific Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Pine Avenue |

Puget Street |

Wilson Street |

Major Collector |

2 |

Existing Major Collector |

|

NE |

Providence Lane |

12th Avenue |

Ensign Road |

Major Collector |

2/3 |

Future Major Collector |

|

NE |

Puget Street |

San Francisco Avenue |

State Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Raft Avenue |

Crestline Boulevard |

Schneider Hill Road |

Major Collector |

2 |

Existing Major Collector |

|

WS |

Road Sixty-Five |

20th Avenue |

14th Avenue |

Major Collector |

2 |

Existing Major Collector |

|

WS |

Road Sixty-Five Connector |

28th Avenue |

Road Sixty-Five |

Major Collector |

2/3 |

Future Major Collector |

|

WS |

Rogers Street |

Bowman Avenue |

4th Avenue |

Neighborhood Collector |

2 |

Existing Neighborhood Collector |

|

WS |

R.W. Johnson Boulevard |

Mottman Road |

21st Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

San Francisco Avenue |

East Bay Drive |

Bethel Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Schneider Hill Road |

West Bay Drive |

Raft Avenue |

Major Collector |

2 |

Existing Major Collector |

|

DT |

Simmons Street |

5th Avenue |

4th Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Sleater-Kinney Road |

North UGB |

6th Avenue |

Major Collector |

2/3 |

Existing Major Collector/Future Left-Turn Needs |

|

NS |

Sleater-Kinney Road |

6th Avenue |

Martin Way |

Major Collector |

4/5 |

Existing Major Collector |

|

NE |

South Bay Road |

Steele Street |

North UGB |

Major Collector |

2 |

Existing Major Collector |

|

NE |

State Avenue |

Pacific Avenue |

Steele Street |

Major Collector |

2 |

Existing Major Collector |

|

SE |

Stoll Road |

Lilly Road |

“North-South” Stoll Road |

Major Collector |

2 |

Existing Major Collector |

|

SE |

Stoll Road (North-South part) |

Stoll Road “T” |

Martin Way |

Major Collector |

2 |

Future Major Collector |

|

DT |

Thurston Avenue |

Capitol Way |

Jefferson Street |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

West Bay Drive |

Harrison Avenue |

Schneider Hill Road |

Major Collector |

2/3 |

Existing Major Collector Modified |

|

SS |

Wheeler Street |

Eastside Street |

Boulevard Road |

Major Collector |

2 |

Existing Major Collector |

|

SS |

Wiggins Road |

27th Avenue |

Yelm Highway |

Major Collector |

2/3 |

Existing Major Collector |

|

NE |

Wilson Street |

12th Avenue |

Pine Avenue |

Major Collector |

2 |

Existing Major Collector |

|

SS |

Wilson Street |

18th Avenue |

22nd Avenue |

Major Collector |

2/3 |

Existing Major Collector |

|

WS |

Yauger Way |

Harrison Avenue |

Forestbrooke Way |

Major Collector |

2/3 |

Existing Major Collector |

(1) If 2/3 or 4/5 lanes are indicated, left-turn channelization may be required for vehicle capacity or safety needs.

(2) For the location of each street, see the Transportation 2030 Maps in Appendix B of the Transportation section of the Comprehensive Plan.

|

Design Standards |

Functional Classification |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Arterial Blvd |

Arterial |

Major Industrial Collector |

Commercial Collector Blvd |

Commercial Collector |

Major Collector Blvd |

Major Collector |

Neighbor-hood Collector Blvd |

Neighborhood Collector |

Local Access |

||

|

|

|

|

|

|

|

|

|

|

|

|

Com. |

Res |

|

Minimum Structural Design |

See Standard Drawing 4-6A |

|||||||||||

|

ADT |

14,000-40,000 |

14,000-40,000 |

3,000-14,000 |

3,000-14,000 |

3,000-14,000 |

3,000-14,000 |

3,000-14,000 |

500-3,000 |

500-3,000 |

0-500 |

N/A |

N/A |

|

Sidewalks |

8' both sides (1)(10) |

8' both sides (1)(10) |

6' both sides (1) |

10' Both sides (10) |

10' Both sides (10) |

6' both sides |

6' both sides |

5' both sides |

5' both sides |

5' both sides |

None |

None |

|

Planting Strips (4) |

10' between curb & walk both sides ----- 14' center median |

10' between curb & walk both sides |

6' between curb & walk both sides |

2-lane = 10' median ----- 4-lane = 14' median |

4-ft in sidewalk adjacent to curb |

8' between curb & walk both sides ----- 14' center median |

8' between curb & walk both sides |

8' between curb & walk both sides (2) ----- 10' median |

8' between curb & walk both sides (2) |

8' between curb & walk both sides (2) |

None |

None |

|

Street Tree Spacing (5) |

40' on center |

40' on center |

40' on center |

40' on center (9)(10) |

40' on center (9)(10) |

40' on center |

40' on center |

40' on center |

40' on center |

40' on center |

None |

None |

|

Parking Lanes |

None (12) |

None |

None |

8' both sides |

8' both sides |

None |

None |

None |

7' one side |

7' one side (6) |

None |

None |

|

Curbs |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

Curb both sides |

None |

None |

|

Lane Widths |

All Arterials and Major Collectors will use 10-foot travel lanes, 5-foot bike lanes and 11-foot center turn lanes. On high frequency bus routes and truck routes, upon evaluation, the City Engineer may require different lane width dimensions to address safety concerns. Street widths will be measured as shown on Standard Drawings for each street classification. |

2 lane - 1'-6' |

1 lane-10' 1 lane-9' |

1 lane-12' |

12 |

Two-36" ribs |

||||||

|

Street widths will be measured as shown on Standard Drawings for each street classification.

|

||||||||||||

|

R-O-W |

2 lanes - 88' 3 lanes - 88' 4 lanes - 104' 5 lanes - 104' |

2 lanes - 68 ’3 lanes - 79' 4 lanes - 88' 5 lanes - 99' |

2 lanes - 56' 3 lanes - 67' 4 lanes - 76' 5 lanes - 87' |

2 lanes - 80' 3 lanes - 84' 4 lanes - 104' (3) |

2 lanes - 68' 3 lanes - 79' 4 lanes - 88' (3) |

2 lanes - 80' 3 lanes - 80' 3 lanes - 96' (3) |

2 lanes - 60' 3 lanes - 71' 4 lanes - 80' (3) |

2 lanes - 74' 2 lanes w/ swale - 70' |

2 lanes - 55' - 65' w/ class II and III 2 lanes w/ swale - 51' - 61' w/ class II and III |

1 lane - 48' 1 lane w/ swale - 44' |

12 |

12 No dead ends |

|

Intersect-ion Radii |

35' turning radius (7) |

35' turning radius (7) |

35' turning radius (7) |

35' turning radius (7) |

35' turning radius (7) |

35' turning radius (7) |

35' turning radius (7) |

25' curb radius (7a) |

25' curb radius (7a) |

30' curb radius (7a) |

N/A |

N/A |

|

Cul-de-sac Radii |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

47' w/ 22' land-scaped island |

N/A |

N/A |

|

Pedestrian Bulb-outs |

Curb bulb-outs required on all Arterials, Major Collectors, Neighborhood Collectors, Commercial Collectors, and streets in the Downtown, where on-street parking exists. Downtown is defined in Chapter 2, and shown in Appendix 4 of this Chapter. |

|

|

|

||||||||

|

Grades |

0.5-8% |

0.5-8% |

0.5-8% |

0.5-10% |

0.5-10% |

0.5-10% |

0.5-10% |

0.5-12% |

0.5-12% |

0.5-15% |

0.5-15% |

0.5-15% |

|

Maximum Design Speeds |

35 mph |

35 mph |

30 mph |

25 mph |

25 mph |

30 mph |

30 mph |

25 mph |

25 mph |

20 mph |

10 mph |

10 mph |

|

Site Access |

See Access Points and Intersection Criteria Guidelines |

20' from inter-section |

20' from inter-section |

20' from inter-section |

N/A |

N/A |

||||||

|

Street Lighting |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Highmast ornament |

Ped Scale |

N/A |

N/A |

|

Access Width |

See Access Points and Inter-section Criteria Guide-lines |

10' at PL 15' at PL Curb |

10' at PL 15' at PL Curb |

|

10' at PL 15' at PL Curb |

N/A |

N/A |

|

|

|

|

|

|

Bicycle Facilities |

Arterials, Major Collectors and selected Neighborhood Collectors will have Class II bicycle facilities, with the exception of those listed in 4D.020.E. Commercial Collectors shall include bike lanes as they apply to Major Collectors and Neighborhood Collectors (refer to section 4D. Bikeways for guidance). |

N/A |

Class II - only for those listed in 4D.020.E |

N/A |

N/A |

N/A |

||||||

Table Notes:

(1) Sidewalk width will be 10 feet in the Central Business District or where the extensions of existing frontage improvements are being extended and the sidewalk width is 10'.

(2) Swale will only be used as an alternative design based on environmental standards. When swale required, swale width = 12' between curb and sidewalk, 6' tree easement opposite side of swale.

(3) The need for left-turn channelization will be evaluated at intersections and access points.

(4) Unless otherwise agreed upon by the City of Olympia, maintenance of street trees, turf or other landscaping within the planting strips is the responsibility of the adjacent landowner.

(5) Street trees required. Exact spacing and species to be determined by Urban Forester. Spacing is approximate - exact spacing will depend on locations of streetlights, fire hydrants, driveways, sign clearance triangles, etc.

(6) Block faces that are greater than 350 feet require parking bulb-outs at both street ends to define parking with a 100 foot No Parking Zone center block.

(7) Turning radius dimensions represent the vehicle turning path. The smallest curb radius should be used while maintaining the specified turning radius. Lane width and the presence of a bike lane and parking lane affect a vehicle’s turning path and allow a smaller radius to be used. All curb radii shall be designed to accommodate a bus, garbage and fire truck turning path. On streets with more than one lane in that direction of travel, large vehicles may encroach into no more than one-half of the adjacent travel lane to complete the turn. On Arterials and Major Collectors, encroachment into oncoming travel lanes is unacceptable. The minimum curb radius is 15 feet.

(7a) At the intersection of two classes of streets, the radius for the higher class of street is used. Where larger truck types are anticipated, further engineering design will be required to determine an adequate radius.

(8) Parking may be required on a case-by-case analysis of neighborhood parking needs.

(9) Street trees in sidewalk section of Commercial Collector will require street tree frames and grates per Standard Drawing 4-49.

(10) Awnings shall conform to OMC 12.24.020 “Awnings.”

(11) In the Chambers Basin R-4CB zone, all streets shall conform to the local ’full-dispersion’ street standard, per Standard Drawing 4-2JX2.

(12) Exceptions to this include where on-street parking exists on an Arterial Street, where such on-street parking can remain.

|

Street Characteristics |

Arterial Street |

Major Collector |

Neighborhood Collector |

Local Access Street |

|---|---|---|---|---|

|

Types of Traffic Served |

Regional and City-wide |

Sub-regional, feed Arterial traffic |

Local traffic, feed Neighborhood/Major Collector or Arterial Traffic |

|

|

Traffic Volumes |

14,000 - 40,000 Average Daily Traffic |

3,000 - 14,000 Average Daily Traffic |

500 - 3,000 Average Daily Traffic |

0 - 500 Average Daily Traffic |

|

Percent Local Traffic |

0 - 15% of origins and destinations are within a one mile radius of the street |

0 - 30% of origins and destinations are within a one mile radius of the street |

70% - 100% of origins and destinations are within a one mile radius of the street |

80% - 100% of origins and destinations within a one mile radius of the street |

|

Average Travel Length |

10 to maximum miles |

2 to 15 miles |

1 to 2 miles |

Minimum to 2 miles |

|

Street Spacing (1) |

1 - 2 miles |

1/2 - 3/4 mile |

1000' - 1500' |

350' - 500' |

|

Intersection Spacing (2) |

≤500' |

350' - 500' |

250' - 350' |

250' - 350' |

|

Design Speed |

30 - 35 mph |

25 - 35 mph |

25 mph |

20 - 25 mph |

|

On-Street Parking |

No - except where parking exists and where exempt. Existing parking may be removed for other Transportation needs. Where parking exists, intersection bulb-outs are required. |

No - except where parking exists and where exempt. Existing parking may be removed for other Transportation needs. Where parking exists, intersection bulb-outs are required. |

Yes - with bulb-outs at intersections. |

Yes - one side with parking bulb-outs to define parking areas. |

|

Driveway Access |

No |

No - except for existing developments |

Yes |

Yes |

|

Bike Lanes (Class II) |

Yes -See 4D.020.E for exceptions. |

Yes - See 4D.020.E for exceptions. |

Some - See 4D.020.E for exceptions |

No |

|

Planting Strips (between sidewalk and curb) |

Yes |

Yes |

Yes |

Yes |

|

Sidewalks |

Yes |

Yes |

Yes |

Yes |

|

Traffic Calming |

No |

As needed |

Yes - if problem is anticipated or determined through an engineering study. |

Yes - if problem is anticipated or determined through an engineering study. |

|

Transit Shelters |

Every 1/2 mile |

Every 1/2 mile |

None |

None |

|

Transit Pullouts |

Every 1/2 mile |

Every 1/2 mile |

None |

None |

Table 3 Notes:

(1) Street spacing means the frequency of street types within the street network.

(2) Intersection spacing means how often a cross street occurs on a particular class of street.

4B.040 Naming

Streets and roads will be named according to specific criteria. The City is divided into four quadrants by Capitol Way (east or west) and 4th Avenue/ Martin Way (north or south). “Avenues” run east-west and are numbered with the exception of certain long-standing historical names. “Streets” run north-south and are named. “Drives” are irregular or diagonal streets over two grid blocks in length not conforming to the grid pattern. “Places” will be a north-south street parallel to but between streets. “Ways” will be an east-west street parallel to but between avenues. “Courts” will be a cul-de-sac that cannot be extended. Courts are to be named or numbered and carry name or the number of the preceding street or avenue. “Loops” will be small loop-type streets to carry the name of the street from which they originate. “Lanes” will be private streets.

An address number will be assigned to all new buildings at the time the building permit is issued. It is then the owner’s responsibility to see that the house numbers are placed clearly and visibly at the main entrance to the property or at the principal place of ingress.

The developer must check with the Public Works Department regarding the naming of streets. This should be done at the time the preliminary plat is submitted and again upon approval of the final plat. The Public Works Department will ensure that the name assigned to a new street is consistent with policies of the City.

4B.050 Signing and Striping

Street signs are defined as any regulatory, warning, or guide signs. The developer is responsible for providing all street signs. Street signs will comply with the latest edition of the U.S. Department of Transportation Manual on Uniform Traffic Control Devices (MUTCD).

Pavement markings and street signs, including posts and hardware, shall be designed, furnished, installed, and paid for by the developer under the City’s direction. The design and installation of all street signs, pavement markings, and associated hardware, will conform to the Washington State Department of Transportation’s Standard Specifications for Road, Bridge and Municipal Construction, in effect at the time of approval for construction, as modified herein, to establish and maintain uniformity.

Plastic pavement markings (preformed tape or sprayed application) shall be used for all transverse, long line, and symbol markings unless otherwise approved by the City Engineer.

Street name signs will display street names, district designation, and grid numbers.

Mast arm street name signs will be pursuant to Standard Drawing 4-37. Post-mounted signs will be pursuant to Standard Drawing 4-45.

4B.060 Right-of-Way

Right-of-way is determined by the functional classification of a street. See Table 1. See Drawing Details 4-2A through 4-2L for specific widths. See Table 2 Street Design Standards for radius requirements at cul-de-sac “bulb.” Right-of-way at “bulb” will be increased accordingly.

Right-of-way requirements may be increased if additional lanes, pockets, transit lanes, bus loading zones, operational speed, bike lanes, utilities, schools, or other factors are required as determined by the Director or Public Works.

Right-of-way will be conveyed to the City on a recorded plat or by a right-of-way dedication or separate instrument.

4B.070 Private Streets

Acceptance as Public Streets. Acceptance of private streets as public streets will be considered only if the streets meet all applicable public street standards, including right-of-way widths.

4B.080 Streetside (Frontage) Improvements

A. All commercial and residential (including multi-family) development, plats, and short plats will install street improvements at the time of construction as required by the Department of Community Planning and Development. Such improvements may include curb and gutter; sidewalk; transit stops, pads, and shelters; street and stormwater; street lighting system; traffic signal modification, relocation, or installation; street trees; utility relocation or installation; undergrounding of franchised utilities; landscaping and irrigation; and street widening, all pursuant to these Standards. Plans will be prepared and signed by a licensed civil engineer registered in the State of Washington.

B. At a minimum, all streetside improvements will be made across the full frontage of the property being developed from centerline to right-of-way line.

Full structural street cross section will be constructed throughout the entire length, including the transition taper. No cross-section taper will be allowed.

C. For Exceptions, see Section 2.040; for Deferrals, see Section 2.070.

D. When streetside improvements are required:

1. Half-street pavement reconstruction will be required when the existing pavement rating is at or below 40, based on the City of Olympia Pavement Management System; crown slope is greater than 3 percent; is light bituminous pavement; and/or was built with no base structure. Section pavement coring and/or subsurface investigation will be required to determine base condition.

2. Half-street asphalt overlay (2-inch minimum) will be required when the existing pavement rating is at or below 60 based on the City of Olympia Pavement Management System. Pre-leveling may be required to create a uniform 2 percent crown slope.

4B.085 Streetside (Frontage) Improvements West Bay Drive

Frontage improvements specific to West Bay Drive will conform to the descriptions contained in Table 4.

|

West Bay Drive Street Section |

Westside of Right-of-Way |

Eastside of Right-of-Way |

|

|---|---|---|---|

|

From |

To |

|

|

|

Roundabouts |

Southern Park Border |

Maintain existing sidewalk location and re-stripe centerline east to provide bicycle lanes north and southbound. (Standard Drawing 4-2G1.) |

Maintain existing sidewalk location and re-stripe centerline east to provide bicycle lanes north and southbound. (Standard Drawing 4-2G1.) Existing on-street parking will be removed. |

|

Southern Park Boundary |

Garfield Nature Trail |

Maintain existing sidewalk location and re-stripe centerline east to provide bicycle lanes north and southbound. (Standard Drawing 4-2G2.) |

Maintain existing sidewalk on the east side of ROW. Re-stripe centerline east to provide bicycle lanes north and southbound. Provide on-street pocket parking/planter. (Standard Drawing 4-2G2.) |

|

Garfield Nature Trail |

Brawne Avenue |

Maintain existing sidewalk location and re-stripe centerline east to provide bicycle lanes north and southbound. (Standard Drawing 4-2G3.) |

Maintain existing sidewalk on the eastside of ROW. Re-stripe centerline east to provide bicycle lanes north and southbound. Bicycle lanes will remain next to the vehicle travel lanes. Sidewalks can be either at street level or below grade. (Standard Drawing 4-2G3.) |

|

Brawne Avenue |

Park Property North Border |

Variable retaining wall, sidewalk and planter strip. (Standard Drawing 4-2G4.) |

The railroad right-of-way will be used for combined trail-sidewalk facility wherever practical and safe. Park trail and sidewalk will be combined in a 10-foot multi-use facility. (Standard Drawing 4-2G4.) |

|

Park Property North Border |

Schneider Hill Base |

Variable retaining wall, sidewalk and planter strip. (Standard Drawing 4-2G5.) |

Bicycle lanes will remain next to the vehicle travel lanes. Sidewalk will be below street grade. If land use remains industrial, trail will be incorporated into the sidewalk. (Standard Drawing 4-2G5.) |

|

Schneider Hill Base |

Schneider Hill Top |

Standard Drawing 4-2G6 |

Standard Drawing 4-2G6. |

|

Schneider Hill Base |

West Bay Marina |

Pocket parking intermixed within planter strip. (Standard Drawing 4-2G7.) |

|

4B.090 Streetside (Frontage) Improvements for Boulevard Road (Standard Drawing 4-2G8)

Table 5 lists the required streetside improvements in various sections of Boulevard Road, working north from Yelm Highway. Refer to Standard Drawing 4-2G8 for more information.

|

From |

To |

Lanes |

|---|---|---|

|

Yelm Highway |

45th Avenue |

2 |

|

45th Avenue |

Boulevard Heights Loop |

3 |

|

Boulevard Heights Loop |

Boulevard Park Court |

2 |

|

42nd Avenue |

41st Way (North Leg) |

2 |

|

Cedar Park Loop (South Leg) |

Cedar Park Loop (North Leg) |

3 |

|

Cedar Park Loop (North of North Leg) |

Log Cabin Road |

2 |

|

Log Cabin Road |

Morse Merryman Road (North Leg) |

2 |

|

31st Avenue (South Leg) |

31st Avenue (North Leg) |

2 |

|

30th Avenue (South Leg) |

31st Avenue (North Leg) |

3 |

|

31st Avenue (North of North Leg) |

28th Avenue (South of South Leg) |

2 |

|

28th Avenue (South Leg) |

28th Avenue (North Leg) |

3 |

|

Fox Avenue (North Leg) |

Swecker Avenue (South of South Leg) |

2 |

|

Swecker Avenue (South Leg) |

Not applicable |

3 |

|

Briar Lea Loop (South Leg) |

Not applicable |

3 |

|

24th Avenue (South Leg) |

24th Avenue (North Leg) |

3 |

|

18th Avenue |

16th Avenue |

2 |

|

Lincoln Avenue (South Leg) |

Not applicable |

2 |

|

15th Avenue (South Leg) |

Not applicable |

2 |

|

Wheeler Avenue (North Leg) |

Not applicable |

2 |

|

9th Avenue (North Leg) |

Not applicable |

2 |

|

7th Avenue (South Leg) |

Not applicable |

2 |

|

The City Engineer will determine locations for median breaks and exclusive left-turn needs. |

||

4B.095 Streetside (Frontage) Improvements East Downtown

|

Street Section |

||

|---|---|---|

|

Cherry Street from 4th Avenue to State Avenue |

• |

Widen sidewalks to 12 feet |

|

• |

Restripe street to a 16-foot one-way lane |

|

|

• |

Maintain parking on both sides |

|

|

• |

Raised mid-block crossing |

|

|

• |

Bulb-outs on corners of 4th Avenue and State Avenue where on street parking exists |

|

|

• |

Stamped colored concrete at crosswalks |

|

|

• |

Underground utilities |

|

|

Chestnut Street from 4th Avenue to State Avenue |

• |

Widen sidewalks to 12 feet |

|

• |

Restripe street to a 16-foot one-way lane |

|

|

• |

Maintain parking on both sides |

|

|

• |

Raised mid-block crossing |

|

|

• |

Bulb-outs on corners of 4th Avenue and State Avenue where on-street parking exists |

|

|

• |

Stamped colored concrete at crosswalks |

|

|

• |

Underground utilities |

|

|

• |

Remove vehicle travel lane, Jefferson to Chestnut (leaving two eastbound lanes), use space for wider parking lanes and bike lane |

|

|

• |

Widen parking lanes to 9 feet |

|

|

• |

Add bike lane on south side of street from Jefferson to Chestnut |

|

|

• |

Rebuild sidewalk, Jefferson to Cherry, retain existing width |

|

|

• |

Add bulb-outs at all corners where on-street parking exists, and extend length of bulb-outs along block faces up to established parking stall |

|

|

• |

Assumes no undergrounding of utilities nor resurfacing, only patching |

|

|

• |

While maintaining south curb line and parking lane, restripe street for two 11-foot travel lanes and a bike lane on the north side |

|

|

• |

Bike lane would extend from Plum to Cherry (no widening required) |

|

|

• |

Relocate 10-foot sidewalk on north side to north edge of right-of-way, provide varying sized planter strip adjacent to relocated parking lane and new bike lane |

|

|

• |

On south side near corner of Plum, widen planter to shadow parking |

|

|

• |

Add bulb-outs on south side at Cherry and at Chestnut where on-street parking exists |

|

|

• |

Widening for bike lane from Cherry to Franklin, with widening |

|

|

• |

Remove travel lane east bound, preserving right turn at Plum |

|

|

• |

Use space for wider sidewalks and bulb-outs at corners and mid-block |

|

|

• |

Widen sidewalks by approximately 5 feet on north and south sides of street |

|

|

• |

Add bulb-outs at corners where on-street parking exists |

|

|

• |

Add mid-block bulb-outs approximately 60 feet long to accommodate larger street trees |

|

|

• |

Remove 1-2 parking stalls for each of 4 mid-block bulb-outs |

|

|

• |

Install large canopy street trees at corners and mid-block |

|

|

• |

Standard street trees in grates |

|

|

• |

Bulb-outs on corners where on-street parking exists |

|

|

• |

Maintain sidewalk width |

|

|

• |

Textured colored concrete in the crosswalks |

|

|

• |

Downtown gateway or entrance signage |

|

4B.110 Half Street

A half street is an otherwise acceptable roadway section modified to conform to limited right-of-way on the boundary of property subject to development. See definition in Chapter 2.

A half street may be permitted, subject to approval by the Public Works Department when:

1. There is reasonable assurance of obtaining the prescribed additional right-of-way from the adjoining property suitable for completion of a full-section roadway; and

2. Such alignment is consistent with or will establish a reasonable circulation pattern; and

3. The right-of-way width of the half street will equal at least 30 feet, or 50 percent of the required right-of-way, whichever is greater; and

4. The traveled way will be surfaced the same as the designated street classification to a width not less than 20 feet; and

5. The half street will be graded consistent with the centerline of the ultimate roadway section; and

6. Property line edge of street will be finished with permanent concrete curb, or curb and gutter to ensure proper drainage, bank stability, and traffic safety.

7. The full street cross-section will be constructed when left-turn channelization, additional vehicle lanes, or medians are required. See Table 2 for design criteria.

4B.120 Medians

A median will be in addition to, not part of, the specified roadway width except on a road classed as a boulevard. Medians will be designed so as not to limit turning radius or sight distance at intersections. Landscaping and irrigation will be installed when directed by the Public Works Director.

For additional guidance on design standards for medians, refer to Section 4I, Access Points and Intersection Criteria.

4B.130 Intersections

A. Traffic control will be as specified in the current edition of the Manual on Uniform Traffic Control Devices (MUTCD) or as modified by the City Engineer as a result of appropriate traffic engineering studies.

B. Street intersections will be laid out so as to intersect as nearly as possible at right angles. Sharp-angled intersections will be avoided. For reasons of traffic safety, a “T” intersection (three-legged) is preferable to a crossroad (four-legged) intersection for local access streets. For safe design, the following types of intersection features should be avoided:

1. Intersection with more than four intersecting streets.

2. “Y”-type intersections where streets meet at acute angles.

3. Intersections adjacent to bridges and other sight obstructions.

4. In no case will the angle of intersection be less than 60 degrees or greater than 120 degrees. The preferred angle of an intersection is 90 degrees.

C. Spacing between adjacent intersecting streets, whether crossing or “T” should be as follows in Table 7.

|

When highest classification involved is: |

Centerline offset should be: |

|

|---|---|---|

|

|

Desirable |

Minimum |

|

Arterial |

≤500 feet |

350 feet |

|

Major Collector |

350-500 feet |

200 feet |

|

Neighborhood Collector |

250-350 feet |

150 feet |

|

Local Access |

250-350 feet |

150 feet |

“Desirable” conditions shall be applied when sufficient space or street frontage is available.

When different class streets intersect, the higher standard will apply on curb radii. Deviations to this may be allowed by the City Engineer per Section 1.050.

D. On sloping approaches at an intersection, landings will be provided with grade not to exceed a 1-foot difference in elevation for a distance of 30 feet approaching any arterial or 20 feet approaching a collector or local access street, measured from the nearest right-of-way line (extended) of intersecting street.

4B.140 Driveways

A. General

This section addresses that portion of the driveway located within the street right of way, also referred to as the driveway approach or entrance. That portion of the driveway located on private property is regulated by Title 18 OMC.

1. Design and construction requirements and details for driveway approaches are located in Table 2 above, section 4I Access Points and Intersection Criteria, and the Standard Drawings appendix of this chapter. Concrete shall be minimum 4,000 psi.

2. All abandoned driveway approaches on the same frontage will be removed and the curb, gutter and sidewalk, or shoulder and ditch section will be properly restored.

3. With the exception of driveway approaches crossing a ditch (with culvert) as detailed in section C below, all driveway approaches will be constructed of impervious Portland Cement Concrete with welded wire fabric reinforcement and will be subject to the same testing and inspection requirements as curb, gutter, and impervious sidewalk construction.

4. Joint-use driveways serving two adjacent parcels may be built on their common boundary upon formal written agreement by both property owners and approval of the City. The agreement will be a recorded easement for both parcels of land specifying joint usage.

5. Grade breaks, including the tie to the street will be constructed as smooth vertical curves. The maximum change in driveway grade will be 8 percent within any 10 feet of distance on a crest and 12 percent within any 10 feet of distance in a sag vertical curve.

6. No commercial driveway approach will be approved where backing onto the sidewalk or street will occur.

B. Arterial and Collector Streets

1. See section 4I, Access Points and Intersection Criteria, for arterial street driveway and access control design criteria.

2. Within the limitations set forth above, access to arterial and collector streets within the City will be limited to one driveway for each tract of property separately owned. Properties contiguous to each other and owned by the same person are considered to be one tract.

3. Driveways giving direct access onto arterial and collector streets may be denied if alternate access is available.

C. Driveway approaches that cross a ditch in the right-of-way (ROW)

For driveway approaches crossing a ditch within the ROW, the culvert under the driveway is to be designed to handle 25-year stormwater flow events in the ditch, of a material designed to handle expected dead and live loads based on depth of cover, and be at least 12 inches in diameter. The culvert pipe shall be beveled and sectioned to match the ditch side slopes, meeting WSDOT Standard Plan B-70.20-00. Driveway material may be asphaltic concrete, and meet the requirements shown in Standard Drawing 4-7F.

4B.150 Sight Obstructions at Intersections

Sight distance standards are important at intersections and driveways so that drivers, bicyclists and pedestrians can see each other, to minimize potential conflicts when approaching and entering these locations. One method to minimize potential conflicts is to require and maintain Clear Sight Triangles.

A. Clear Sight Triangle. The Clear Sight Triangle at each corner of every intersection is a volume of space inside which no permanent obstructions, except those listed in subsection D below, are allowed. The height of this volume of space is between 2.5 feet and 10 feet above the ground surface. The length, or sides, of this triangle will vary by type of intersection, as discussed below, but in no case shall be less than 20 feet on a frontage side, as shown in Standard Drawing 4-1A. Clear Sight Triangle requirements also apply to both sides of commercial driveway approaches.

The area within the Clear Sight Triangle shall be free from all obstructions, except those identified in subsection D below, to maintain a clear view on the intersection approaches. So, for example, if not otherwise prohibited a fence may be constructed along the property boundary at an intersection, but must be less than 2.5 feet tall, so as not to extend into the Clear Sight Triangle at that intersection.

B. Stop or Yield Controlled Intersection. The Intersection Sight Distance criteria given in Table 8 is for Stop or Yield Controlled Intersections, and is based on Table 9-6 of A Policy on Geometric Design of Highways and Streets published by AASHTO (2011). This table applies to intersection and driveways with an ADT greater than 20. For driveways with an ADT of 20 or less, the Stopping Sight Distance on page 3-4 of this AASHTO publication can be used. An example is shown in Standard Drawing 4-1C.

|

Operating Speed |

Intersection Sight Distance |

Stopping Sight Distance |

|

|---|---|---|---|

|

2 Lanes |

4+ Lanes |

||

|

20 mph |

225 feet |

240 feet |

115 feet |

|

25mph |

280 feet |

295 feet |

155 feet |

|

30mph |

335 feet |

355 feet |

200 feet |

|

35 mph |

390 feet |

415 feet |

250 feet |

Other factors, such as vertical and horizontal curves and roadway grades, also need to be taken into account. Such factors can require necessary modification to the intersection sight distance given in this table.

C. Uncontrolled Intersection. At uncontrolled intersections, the Clear Sight Triangle may be increased in size from the minimum dimensions described in subsection A above, based on the dimensions indicated in Table 9.

|

|

Sight Distance |

|

|---|---|---|

|

Speed Limit |

(A) Major Street |

(B) Minor Street |

|

20 mph |

90 feet |

90 feet |

|

25 mph |

115 feet |

115 feet |

|

30 mph |

140 feet |

140 feet |

|

35 mph |

165 feet |

165 feet |

D. Exclusions. Sight obstructions that may be allowed in the Clear Sight Triangle include utility poles, regulatory signs, trees trimmed from the base to a height of 10 feet above the street, places where the contour of the ground is such that there can be no cross visibility at the intersection, buildings constructed in conformance with the provisions of appropriate zoning regulations and preexisting buildings. In addition, the requirements of OMC section 18.40.060.B shall also apply. In the case of conflicts between the OMC and the EDDS regarding Clear Sight Triangles, the more restrictive requirement shall apply.

4B.160 Surfacing Requirements

The following are the surfacing requirements for each application listed.

A. Asphalt Pavements. The minimum pavement sections listed in Standard Drawing 4-6A are in lieu of pavement design and are based on subgrade California Bearing Ratio (CBR) value of 3. Alternate structures will be accepted based on soil tests to determine the actual CBR value and completion of Worksheet 4-6B in Chapter 4 drawings. Soil tests and a completed worksheet for each street classification shall accompany plans submitted if other than the structures shown below and pavement sections in Detail 4-6A is used.

One soil sample per each 250 LF of centerline with three minimum per project representative of the roadway subgrade shall be taken to determine a statistical representation of the existing soil conditions.

The soils report, signed and stamped by a professional engineer licensed by the State of Washington, shall be based on actual soils tests performed by an engineering firm specializing in soils analysis and submitted with the plans. All depths indicated are a minimum compacted depth.

Existing pavement restoration for utility or street widening projects requiring restoration of existing pavement, additional information, and design will be required to ensure pavement meets restoration requirements shown in Table 10: Pavement Restoration Requirements. The information required may include: (1) pavement cores representative of typical pavement sections; and (2) statement of existing pavement condition and discussion of how it will “match up” to the new pavement section.

For asphalt concrete paving requirements for streets, see Section 4B.175.

B. Sidewalks

|

Surfacing: |

4-inch pervious concrete |

|

Base: |

4-inch ballast and underdrain system per Standard Drawing 4-9C |

|

Alternate: |

|

|

Surfacing: |

4-inch commercial concrete |

|

Base: |

2-inch crushed surfacing top course or well-graded sand |

Asphalt sidewalks will not be permitted, unless approved through the deviation process outlined in section 1.050.

C. Driveway Approach

|

Surfacing: |

9-inch commercial concrete |

|

Base: |

2-inch crushed surfacing top course or well-graded sand |

D. Class I Bikeway

|

Surfacing: |

4-inch commercial concrete |

|

Base: |

2-inch crushed surfacing top course |

|

|

|

|

Alternate: |

|

|

|

|

|

Surfacing: |

2 1/2 inch Commercial Hot Mix Asphalt (HMA) |

|

Base: |

4-inch ballast |

|

|

|

|

Alternate: |

|

|

|

|

|

Surfacing: |

4-inch pervious concrete |

|

Base: |

4-inch ballast and underdrain system per Standard Drawing 4-9C |

Pervious concrete materials shall only be used in locations where topography and soil conditions are appropriate.

4B.170 Temporary Street Patching

Temporary restoration of trenches will be accomplished by using one of the following:

A. Commercial HMA,

B. Cold asphalt patching material consisting of PG 58-22 liquid asphalt and aggregate meeting AASHTO T-30 gradation, or

C. Steel plates. Asphalt ramps shall be established for steel plate edges facing traffic.

Commercial HMA or cold patch asphalt for temporary restoration may be placed directly into the trench, bladed and rolled to provide a smooth-riding surface. The minimum thickness of the compacted material must be 2 inches or the thickness of the existing asphalt, whichever is greater.

Prior to beginning street trenching work, the contractor will ensure that temporary patching material is stockpiled at the project site, both for completing and maintaining the temporary patching.

All temporary patches will be maintained by the contractor and will be made permanent within three (3) working days. Patches that are not properly maintained will be identified by the City Construction Inspector and repaired by the City at the property owner, permit holder, or private utility’s expense.

4B.175 Pavement Restoration

A. Introduction. Trench cuts and other invasive pavement cuts such as “windowing” for pipe depth verification and service line connections in roadways greatly degrade the condition of the pavement, as well as reduce the design life. The most significant damage can be seen in newer pavements. A restored pavement cut in a newly paved street lowers the Pavement Management System (PMS) rating 30 points (on a scale of 0 to 100). It is the goal of pavement restoration to have a pavement in better or as good as pre-pavement cut condition. This can be achieved through prevention of pavement cuts through utility coordination, and high-quality pavement restoration.

B. Lane width restoration requirements. For longitudinal utility trench cuts in pavements over five years old, a minimum 2-inch overlay or full-depth pavement reconstruction is required for the following widths:

1. One-lane overlay or reconstruction: when trench cut or patch is within one travel lane.

2. Two-lane overlay or reconstruction: when trench cut or patch is within two travel lanes.

3. Additional overlay or reconstruction: when the remaining pavement area to the edge of existing pavement on either side is less than one travel lane or pavement is less than five years old. No longitudinal joints will be allowed in the wheel path.

C. Pavement restoration requirements. Table 10: Pavement Restoration Requirements describes pavement restoration requirements for various size projects and various existing pavement conditions.

D. Transverse utility crossings. Transverse utility crossings must be bored or completed by another trenchless method. Bore pits must be restored pursuant to Section 4B.175(C).

E. Pavement cuts in new pavements. Pavement cuts, including “windowing” for pipe depth and/or location verification, are not permitted in pavements that have been constructed or rehabilitated within five years. Rehabilitation includes all asphalt overlays. If there is no other option but to cut into new pavement, the pavement must be restored pursuant to Table 10: Pavement Restoration Requirements.

F. Exemption from pavement restoration requirements and financial penalties. Utilities can appeal in writing directly to the Public Works Director for exemption from pavement restoration requirements and financial penalties associated with cutting into new pavements.

Utilities may be exempt from pavement financial penalties if there is no other viable alternative and under the following conditions:

1. If the City failed to give six months’ notice of an upcoming roadway rehabilitation project either because of:

a. a change in property ownership, or

b. a change in the City’s Capital Facilities Plan, or

c. streets and roads associated with the Street Repair Least-Cost Program.

2. An emergency project requiring immediate attention for the preservation of life or property.

|

Existing Pavement Condition |

|||

|---|---|---|---|

|

Project Type |

New Pavements Less Than 5 Years Old |

Pavements Greater Than 5 Years Old |

Pavements Identified by the City to be Reconstructed Within 2 Years |

|

Large Projects Consists of a project requiring a longitudinal trench cut through the paved roadway surface 50 linear feet or greater, or four or more traverse trench cuts per 300 linear feet of roadway. |

Complete reconstruction, grind/inlay, or overlay of entire paved surface (all lanes). Pavement section based on pavement design.* |

Grind/inlay, reconstruct, or overlay. Width per lane requirements in Section 4B.175. Pavement section based on pavement design. |

Depending on intended reconstruction strategy, could utilize lesser pavement restoration. Minimum restoration is patch pursuant to Standard Drawing 4-8. |

|

Small Projects Consists of a project requiring a longitudinal trench cut through the paved roadway surface less than 50 linear feet or less than four pavement cuts per 300 linear feet of roadway. |

Patch pursuant to Standard Drawing 4-8. Pavement restoration fee assessed per OMC 12.20.270. |

Patch pursuant to Standard Drawing 4-8. |

Depending on intended reconstruction strategy, could utilize lesser pavement restoration. Minimum restoration is patch pursuant to Standard Drawing 4-8. |

|

Emergency Projects A project that could not be foreseen requiring immediate attention for the preservation of life or property. |

Grind/inlay, reconstruct, overlay, or patch (dependent on project size [see above]). Width pursuant to lane requirements in Section 4B.175. Pavement section based on pavement design. |

Grind/inlay, reconstruct, overlay, or patch (dependent on project size [see above]). Width pursuant to lane requirements in Section 4B.175. Pavement section based on pavement design. |

Depending on intended reconstruction strategy, could utilize lesser pavement restoration. Minimum restoration is patch pursuant to Standard Drawing 4-8. |

|

Septic to Sewer Projects Consists of a sewer main extension for a single property converting to a public sewer connection without an increase in ERUs. |

Patch pursuant to Standard Drawing 4-8. Pavement restoration fee assessed per OMC 12.20.270, unless the project is the result of a failed septic system. |

Patch pursuant to Standard Drawing 4-8. |

Patch pursuant to Standard Drawing 4-8. |

* If it is determined by the Public Works Director that full paved surface restoration impacts are excessive (i.e., traffic congestion, business impacts), restoration can be reduced to trench restoration only and a fee-in-lieu equal to the cost of full paved surface restoration assessed.

G. Construction Requirements

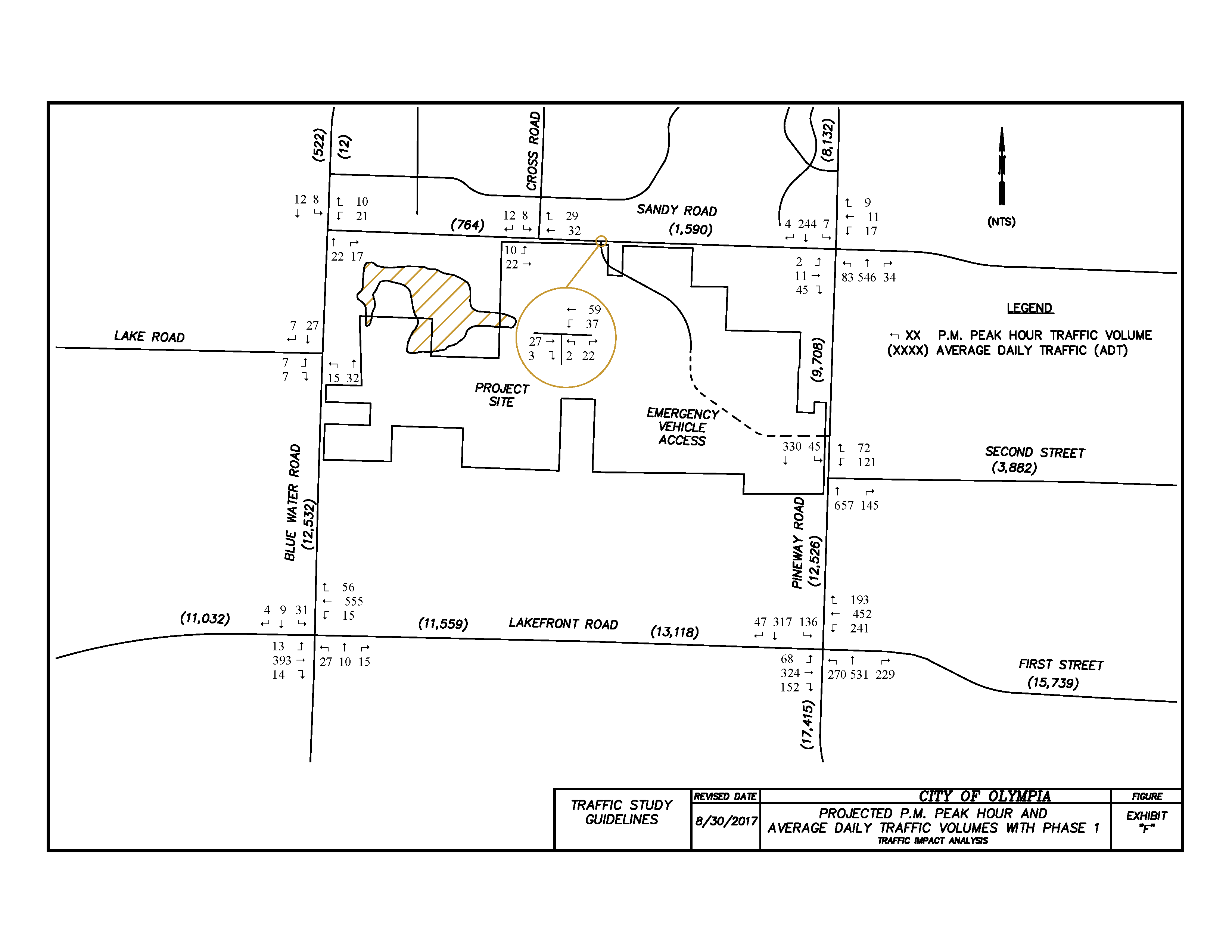

1. All trench and pavement cuts will be made uniformly by wheel or saw cutting. If edge of trench line degrades, ravels, or is non-uniform, additional saw cutting will be required prior to final patch or paving.